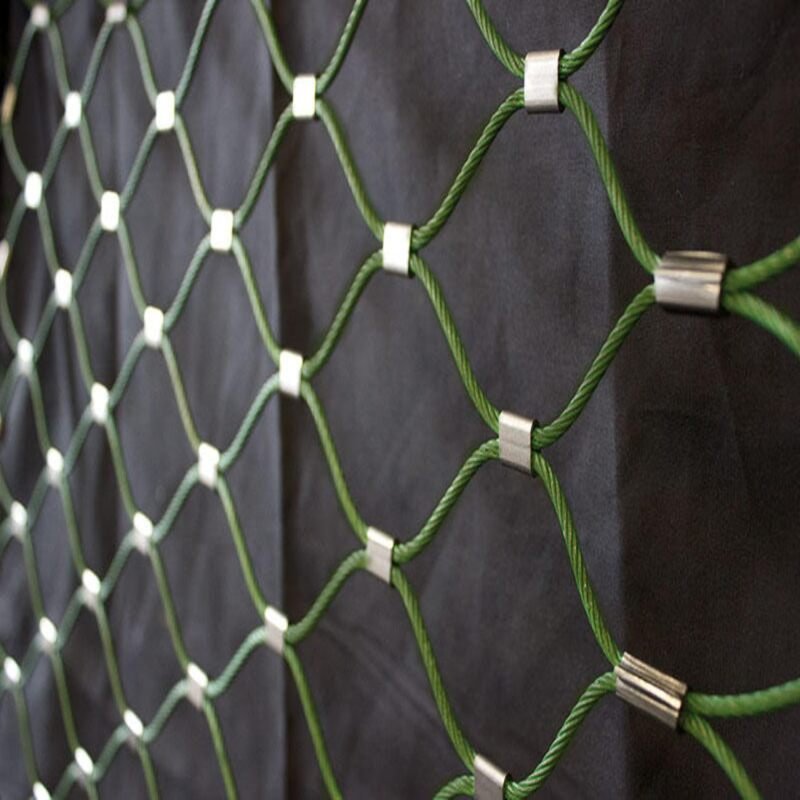

Stainless steel woven wire rope mesh, a creation of BMP, brings versatility, durability, and aesthetics into one extraordinary product. The mesh, crafted from high-grade stainless steel cables (AISI316 / AISI316L; 1.4401), boasts an adaptable design. The X-tend type cable mesh can be customized to complement your balustrade, railing, or architectural aspirations. Furthermore, the mesh can be installed in vertical or horizontal orientations, with possibilities extending to diagonal and irregular shapes.

To produce stainless steel woven wire rope mesh, manufacturers follow several steps:

- Select Material: First, choose high-quality stainless steel wire, typically in grades 304, 304L, 316, or 316L, for its corrosion resistance and strength.

- Weave Cables: Next, weave the stainless steel cables together. This can involve hand weaving for custom patterns or using machines for standard designs. The weaving process interlocks the wires, creating the mesh structure.

- Form Knots or Use Ferrules: For knotted mesh, tie precise knots at each intersection. For ferrule types, insert metal ferrules at cable intersections and crimp them securely. This step is crucial for the mesh’s overall strength and flexibility.

- Cut to Size: After weaving, cut the mesh into panels according to the project’s specifications. Use specialized tools to ensure clean cuts and prevent fraying.

- Inspect and Finish: Carefully inspect each panel for consistency and quality. Finish the edges and corners to make them safe for handling and installation.

- Pack and Ship: Finally, pack the mesh panels for shipping. Use protective packaging to prevent damage during transport.

Embracing Unique Characteristics

Our stainless steel woven wire rope mesh has skin-like characteristics, forming a plane surface that can be tensioned into three-dimensional forms. The result? Mesh forms that encapsulate funnel-like, cylindrical, or spherical shapes, adapting to your specific needs.

Specifications: A Closer Look

The stainless steel woven wire rope mesh comes in a variety of specifications, including Black Oxide Stainless Steel Wire Rope Zoo Mesh (Ferruled Type). The mesh specifications vary in rope diameter, mesh aperture, and normal break, all designed to cater to different requirements.

For example, the YT-3212F type has a rope diameter of 1/8 inch or 3.2 mm, a mesh aperture of 4.75 x 8.23 inches or 120 x 207.8 mm, and a normal break of 1600 lbs. The specifications continue down to YT-1220F, providing a plethora of options for different applications.

A Detailed Look at Specifications Woven Wire Rope Mesh

| Item No.s |

Rope Diameter(inch/mm) |

Mesh Aperture(W x H)(inch/mm) |

Normal Break(lbs) |

| YT-3212F |

1/8 / 3.2 |

4.75 x 8.23 / 120 x 207.8 |

1600 |

| YT-3210F |

1/8 / 3.2 |

4 x 6.9 / 102 x 156 |

1600 |

| YT-3290F |

1/8 / 3.2 |

3.55 x 6.15 / 90 x 156 |

1600 |

| YT-3276F |

1/8 / 3.2 |

3 x 5.2 / 76 x 131.6 |

1600 |

| YT-3251F |

1/8 / 3.2 |

2 x 3.46 / 51 x 88.3 |

1600 |

| YT-2410F |

3/32 / 2.4 |

4 x 6.9 / 102 x 176.7 |

920 |

| YT-2490F |

3/32 / 2.4 |

3.55 x 6.15 / 90 x 156 |

920 |

| YT-2476F |

3/32 / 2.4 |

3 x 5.2 / 76 x 131.6 |

920 |

| YT-2460F |

3/32 / 2.4 |

2.4 x 4.16 / 60 x 104 |

920 |

| YT-2451F |

3/32 / 2.4 |

2 x 3.46 / 51 x 88.3 |

920 |

| YT-2076F |

5/64 / 2.0 |

3 x 5.2 / 76 x 131.6 |

676 |

| YT-2060F |

5/64 / 2.0 |

2.4 x 4.16 / 60 x 104 |

676 |

| YT-2051F |

5/64 / 2.0 |

2 x 3.46 / 51 x 88.3 |

676 |

| YT-2038F |

5/64 / 2.0 |

1-1/2 x 2.6 / 38 x 65.8 |

676 |

| YT-1676F |

1/16 / 1.6 |

1.2 x 2.08 / 76 x 131.6 |

480 |

| YT-1651F |

1/16 / 1.6 |

2 x 3.46 / 51 x 88.3 |

480 |

| YT-1638F |

1/16 / 1.6 |

1-1/2 x 2.6 / 38 x 65.8 |

480 |

| YT-1630F |

1/16 / 1.6 |

1.2 x 2.08 / 30 x 52 |

480 |

| YT-1625F |

1/16 / 1.6 |

1 x 1.73 / 25.4 x 44 |

480 |

The Power of Choice: Mesh Aperture Direction

Mesh aperture direction is another important aspect, offering two directions: horizontal and vertical. This flexibility further enhances the versatility of the stainless steel woven wire rope mesh, allowing it to fit seamlessly into your design.

Understanding the Chemical Composition

Knowledge of the chemical composition of the stainless steel wire rope aids in selecting the ideal mesh for your needs. The three variants – SS304, SS316, and SS316L – each have unique compositions to provide different strengths and properties.

Woven Wire Rope Mesh Types

Our woven wire rope mesh comes in different types, including the stainless steel variant, which offers added resilience and aesthetic appeal.

Key Features Woven Wire Rope Mesh

Our stainless steel woven wire rope mesh is renowned for its durability, flexibility, and aesthetic appeal. It’s the perfect solution for a variety of applications, offering a blend of functionality and beauty.

Applications: Unlimited Possibilities

Stainless steel woven wire rope mesh finds its applications in a multitude of areas. From providing safety in zoos with animal enclosures to enhancing architectural aesthetics, the application of wire rope mesh is virtually limitless.

In conclusion, stainless steel wire rope mesh is a versatile, resilient, and visually appealing product. It’s your ultimate solution for varied applications that demand durability and elegance.