Stainless steel wire rope mesh is a very flexible and strong material made from top-quality stainless steel cable. You can get this mesh in stainless steel grades like type 304, 304L, 316, and 316L. It is available in structures with 7 x 7 and 7 x 19 cable configurations. With many standard mesh sizes and diameters, various industries use this mesh. These industries include hotels, shopping malls, supermarkets, offices, and spaces for indoor decoration, mechanical protection, electrical ventilation, and aquaculture.

Specifications:

| Specification |

Details |

| Material |

AISI standard 304/316 stainless steel rope |

| Structure |

7×7 or 7×19 |

| Rope diameter |

1.0mm, 1.5mm, 2.0mm, 3.0mm, 4.0mm |

| Mesh size |

60mm or 80mm |

| Panel height |

720mm, 840mm, 960mm (custom height available) |

| Frame material |

Welded galvanized steel or AISI316 stainless steel tubular frame |

| Frame diameter |

17.2mm to 26.9mm |

| Frame wall thickness |

2mm |

| Mesh opening size |

20mm x 35mm to 200mm x 346mm |

| Mesh barrier assembly |

Seamless ferrules and stainless steel wire rope |

| Mesh barrier angle |

60° (option for 20°-90° angle) |

| Features |

High strength, soft and flexible, corrosion-resistant, handmade, glare-free, eco-friendly |

| Applications |

Bridge, path, stair, balcony balustrades |

| Top specifications |

MBRE-1, MBRE-2, MBRE-3, MBRE-4 |

| Mesh structure |

BOSSMETAL (various opening width and height) |

| Opening width |

20mm to 200mm |

| Opening height |

35mm to 346mm |

| Opening gauge |

60° standard (angle option: 30°-90°) |

Early Developments

The history of stainless steel began in the early 20th century. In 1913, English metallurgist Harry Brearley discovered a steel alloy with 12.8% chromium and 0.24% carbon, which was remarkably resistant to corrosion. This discovery marked the birth of “stainless steel.” Initially, its corrosion-resistant properties made it popular for cutlery and surgical instruments.

Expansion into Structural Applications

By the mid-20th century, as metallurgical processes advanced, manufacturers began to explore the use of stainless steel in more structural applications. The strength, flexibility, and anti-corrosive properties of stainless steel led to its use in constructing cables and eventually, wire rope meshes.

Introduction of Wire Rope Mesh

The actual development of stainless steel wire rope mesh is not documented with a precise date but is understood to have evolved as the qualities of stainless steel became more appreciated in heavy-duty applications. These included bridges, industrial machinery, and eventually, architectural uses.

Architectural and Safety Applications

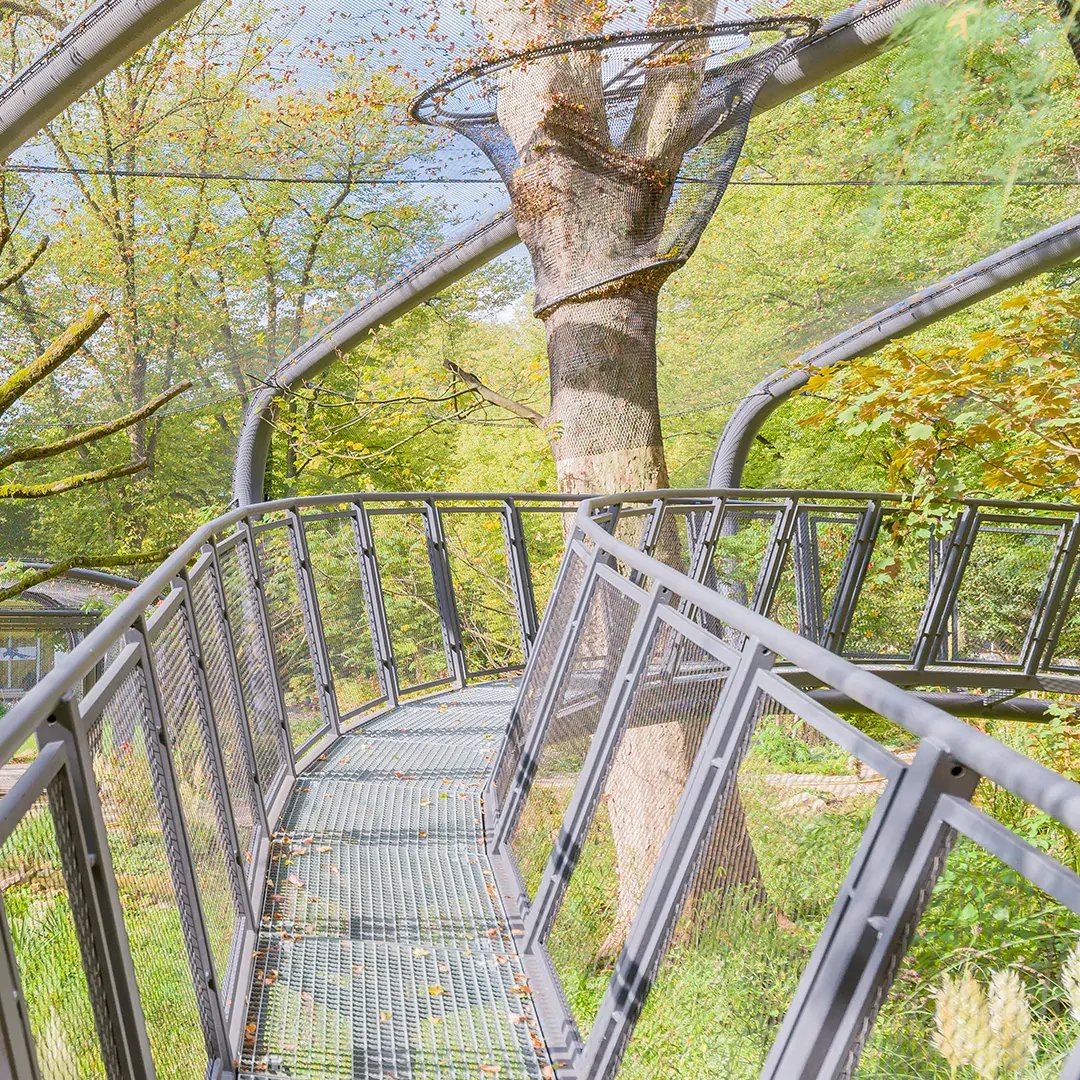

By the late 20th century, architects and engineers began utilizing stainless steel wire rope mesh for its aesthetic appeal and structural integrity. It found applications in facades, balustrades, and other forms of decorative yet functional barriers. Its transparency and strength made it an excellent choice for safety barriers in zoos and animal enclosures, allowing clear visibility without compromising the safety of animals or visitors.

Modern Innovations

In recent decades, the production techniques for stainless steel wire rope mesh have become more sophisticated. The introduction of automated and precision engineering has allowed for the production of meshes with varying degrees of thickness, mesh size, and flexibility, making it suitable for a wider range of applications from safety nets in construction sites to intricate designs in architectural projects.

Today’s Usage

Today, stainless steel wire rope mesh is widely used across various industries due to its durability, flexibility, and minimal maintenance needs. It’s found in zoological designs, marine parks, architectural aesthetics, and even in public safety applications such as slope stabilization and fall protection in industrial environments.

Features:

- High flexibility and adaptability

- Anti-corrosion and rust-resistant

- High strength and strong toughness

- Can be bent and folded for easy transportation and installation

- Resistant to chewing by rodents and other pests

- Can withstand heavy snow and gale-force winds

- Non-toxic, safe, and environmentally friendly

Advantages:

- Durability: The stainless steel material resists corrosion and rust well, ensuring a long lasting and low-maintenance solution.

- Versatility: You can customize the mesh to different shapes, sizes, and cable structures to fit various applications.

- Aesthetic Appeal: Stainless steel wire rope mesh has a sleek and modern look that complements any architectural design.

- Security: The high-strength mesh creates a strong barrier against intrusion and works well for security fencing or reinforcement.

Applications: Here are some ways people use stainless steel wire rope mesh:

Architectural and Interior Design: For building fronts, ceilings, stair railings, and indoor decor.

Zoos and Marine Parks: For animal homes, bird nets, and animal fences.

Public Spaces: In parks, for community safety, on doors, windows, and in garden decor.

Industry: As covers to protect machines, for air flow in electrical systems, and in fish farming.

Building Reinforcement and Security: For lifting items, sealing cars, protecting slopes, supporting mines, and preventing break-ins.

Exploring the Types of Stainless Steel Rope Mesh

Stainless steel rope mesh is a highly versatile material known for its strength, durability, and resistance to corrosion. It’s perfect for many different industries. Here are the common types of stainless steel rope mesh and what they are best for:

- Cable Netting Workers make cable netting from woven stainless steel cables. It’s famous for its flexibility and strength. People often use it for projects that need to look good and last long, like building facades, zoo enclosures, and safety nets in factories.

- Stainless Steel Wire Rope Mesh This type of mesh is like cable netting but offers even greater strength and can support more weight. It’s perfect for suspension bridges, staircases, and railings where safety is key.

- Knotted Cable Mesh Workers make knotted cable mesh by tying stainless steel cables at the intersections. This makes a secure and stiff structure. It’s especially good for outdoor uses like bird aviaries and large animal enclosures where you need strong barriers.

- Ferrule Type Cable Mesh In ferrule type cable mesh, workers connect stainless steel cables at intersections using ferrules, which are either cylindrical or diamond-shaped metal sleeves. This mesh type is very flexible and looks nice, making it great for decorative uses, green walls, and building exteriors.

- Square Cable Mesh Square cable mesh has a grid-like structure with square openings, giving it a uniform and geometric look. This type is often used in modern architecture to create impressive facades or interior walls that blend visibility with protection.

Conclusion:

Stainless steel wire rope mesh is versatile, durable, and aesthetically pleasing, serving multiple industries well. You can customize its specifications to meet specific project requirements, making it a top choice for architects, designers, and engineers. Its anti corrosive properties, strength, and flexibility ensure it lasts long and offers cost-effectiveness. This makes it a reliable solution for various applications