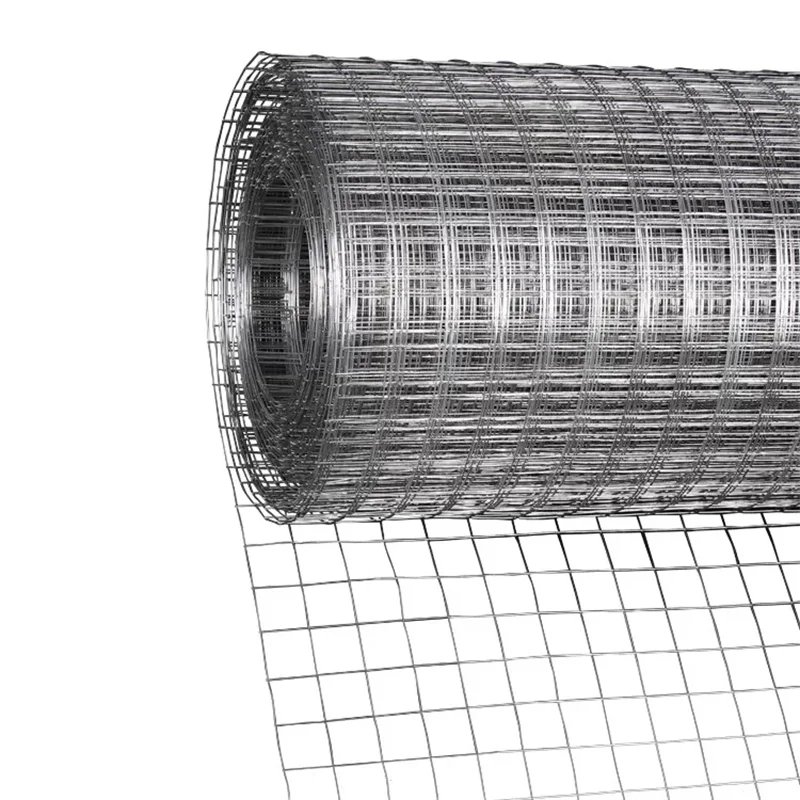

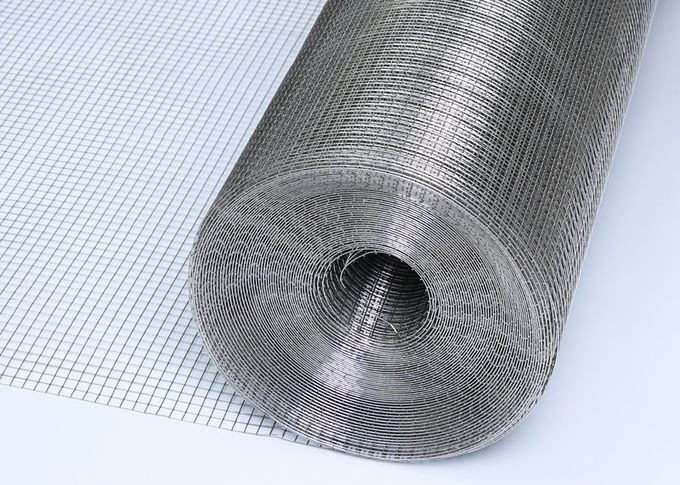

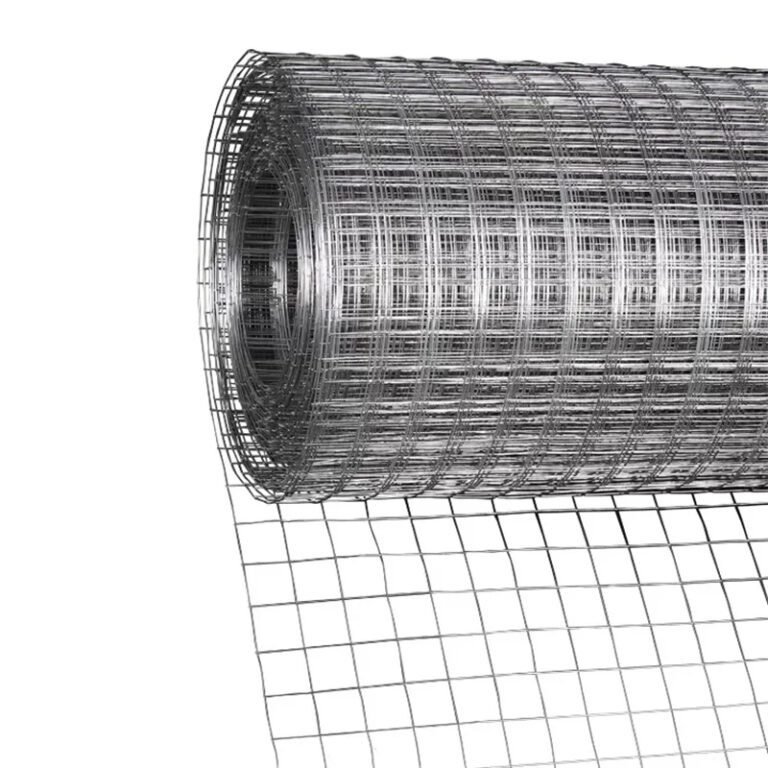

Welded wire mesh made from stainless steel is a robust and adaptable material used across a wide range of industries. Created by welding steel wires at their intersections, it forms a rigid and uniform grid that offers strength, corrosion resistance, and long-term durability. Whether in industrial settings, construction, agriculture, or architecture, it provides reliable performance in demanding environments.

Characteristics Stainless Welded Wire Mesh

1. Material Composition

Manufactured primarily from grades 304 or 316 stainless steel, this mesh offers excellent resistance to rust, chemicals, and extreme temperatures. Grade 304 is ideal for general use, while 316 is preferred in marine or chemically aggressive environments due to its molybdenum content.

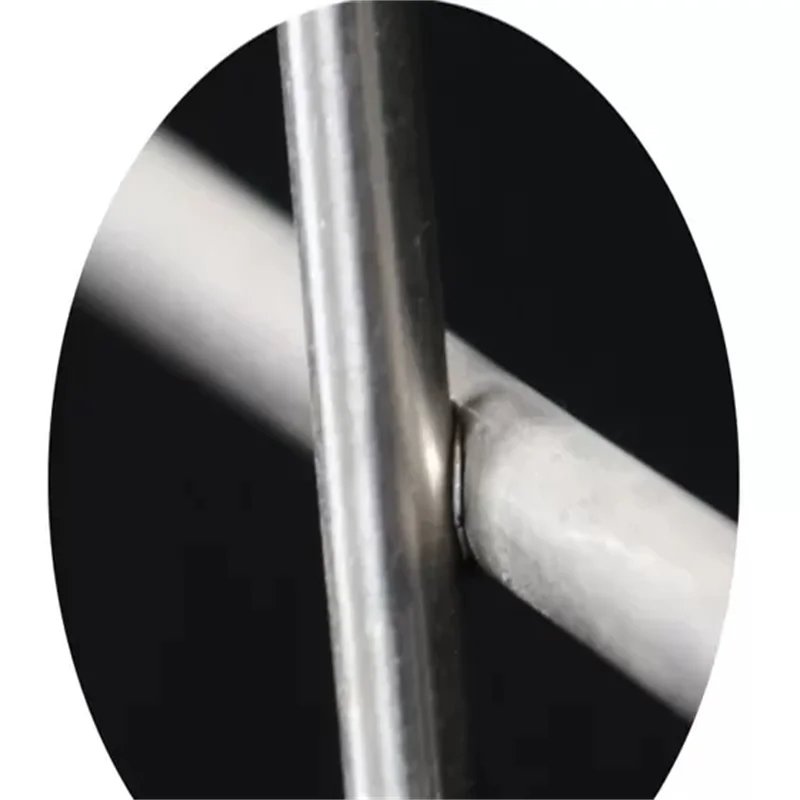

2. Welding Process

The mesh is produced through an electrical resistance welding technique, ensuring strong joints at each intersection. This prevents unraveling and maintains structural integrity even when cut.

3. Mesh Configuration

- Square or Rectangular Openings

- Wire diameters range from 0.5 mm to over 2.5 mm

- Opening sizes typically range from 6 mm to 50 mm

Specification Table Stainless Welded Wire Mesh

Stainless Steel Welded Wire Mesh Specifications

| Mesh Size (inches) |

Wire Diameter (mm) |

Wire Gauge (BWG) |

Opening Size (mm) |

Open Area (%) |

Typical Application |

| 1/4″ x 1/4″ |

0.56 – 0.71 |

24 – 22 |

~6.35 |

~80 – 85 |

Filtration, rodent control, fine screening |

| 3/8″ x 3/8″ |

0.64 – 1.07 |

23 – 19 |

~9.5 |

~75 – 80 |

Machine guarding, ventilation |

| 1/2″ x 1/2″ |

0.71 – 1.65 |

22 – 16 |

~12.7 |

~70 – 80 |

Bird cages, fencing, sieving |

| 3/4″ x 3/4″ |

0.81 – 1.65 |

21 – 16 |

~19.1 |

~70 – 80 |

Animal cages, barriers |

| 1″ x 1″ |

0.81 – 2.11 |

21 – 14 |

~25.4 |

~80 – 90 |

General fencing, storage bins |

| 1″ x 2″ |

1.47 – 2.11 |

17 – 14 |

~25.4 x 50.8 |

~85 – 90 |

Partitions, ventilation guards |

| 2″ x 2″ |

1.65 – 2.77 |

16 – 12 |

~50.8 |

~85 – 90 |

Heavy-duty fencing, security mesh |

🔧 Stainless Steel Welded Wire Mesh – Specification Table

| Code |

Mesh Size (inch) |

Mesh Size (mm) |

Wire Gauge (SWG) |

Wire Diameter (mm) |

Weight (kg/m²) |

| BMPSS-1 |

1/4″ × 1/4″ |

6.4 × 6.4 |

22# – 24# |

0.6 – 0.7 |

0.72 – 0.98 |

| BMPSS-2 |

3/8″ × 3/8″ |

10.6 × 10.6 |

19# – 22# |

0.7 – 1.0 |

0.65 – 1.3 |

| BMPSS-3 |

1/2″ × 1/2″ |

12.7 × 12.7 |

16# – 23# |

0.6 – 1.6 |

0.36 – 2.56 |

| BMPSS-4 |

5/8″ × 5/8″ |

16 × 16 |

18# – 21# |

0.8 – 1.2 |

1.2 – 1.3 |

| BMPSS-5 |

3/4″ × 3/4″ |

19.1 × 19.1 |

16# – 21# |

0.8 – 1.6 |

0.4 – 1.7 |

| BMPSS-6 |

1″ × 1/2″ |

25.4 × 12.7 |

16# – 20# |

0.9 – 1.6 |

0.61 – 1.92 |

| BMPSS-7 |

1″ × 1″ |

25.4 × 25.4 |

14# – 21# |

0.8 – 1.2 |

0.32 – 2 |

| BMPSS-8 |

1 1/2″ × 1 1/2″ |

38 × 38 |

14# – 19# |

1.0 – 2.0 |

0.3 – 1.3 |

| BMPSS-9 |

1″ × 2″ |

25.4 × 50.8 |

14# – 16# |

1.6 – 2.0 |

3.84 – 6 |

| BMPSS-10 |

2″ × 2″ |

50.8 × 50.8 |

12# – 16# |

1.6 – 2.6 |

0.25 – 1.6 |

| BMPSS-11 |

2″ × 3″ |

50 × 75 |

13# – 16# |

1.6 – 2.3 |

0.53 – 1.10 |

| BMPSS-12 |

3″ × 3″ |

75 × 75 |

12# – 16# |

1.6 – 2.6 |

0.17 – 0.43 |

| BMPSS-13 |

2″ × 4″ |

50 × 100 |

13# – 14# |

2.0 – 2.3 |

0.75 – 0.99 |

| BMPSS-14 |

4″ × 4″ |

100 × 100 |

13# – 14# |

2.0 – 2.3 |

0.5 – 0.66 |

| BMPSS-15 |

8″ × 8″ |

200 × 200 |

13# – 14# |

2.0 – 2.3 |

0.25 – 0.33 |

📐 Available Dimensions

- Panels:

3′ × 6′, 4′ × 8′, 5′ × 10′

1 m × 2 m, 1.2 m × 2.4 m, 1.5 m × 3 m, 2 m × 4 m

- Rolls:

Standard width: 2400 mm

Length: Customizable upon request

🔩 Material Grades Available Stainless Steel Welded Wire Mesh

- SS201, SS202, SS302, SS304, SS304L, SS316, SS316L

📦 Packing

- Rolls wrapped in waterproof paper

- Panels packed on wooden pallets

- Custom packaging available on request

Material Options

| Grade |

Description |

| SS304 |

Most common, good corrosion resistance, indoor/outdoor use |

| SS316 |

High corrosion resistance, suitable for marine/chemical use |

Available Forms

- Rolls: Up to 48″ wide, lengths up to 100 ft

- Panels: Common sizes: 4′ x 8′, 4′ x 10′ (custom sizes available)

Surface Finish Options

- Mill finish: Standard raw stainless surface

- Electropolished: Enhanced corrosion resistance and aesthetic finish

- Pickled & passivated: For extra protection in aggressive environments

Applications Stainless Welded Wire Mesh

- Industrial: Conveyor belts, safety guards, drying racks

- Construction: Concrete reinforcement, partition walls

- Agriculture: Animal cages, grain storage bins

- Architecture: Decorative panels, facades, fencing

- Food & Pharma: Sanitary trays, equipment guards

Advantages

- Long service life with minimal maintenance

- Withstands weathering, chemical exposure, and physical impact

- Easy to fabricate, weld, or cut on-site

- Hygienic and compliant with food-grade standards

Conclusion

Welded mesh in stainless steel is a practical and efficient solution for users needing structural strength, reliability, and resistance to corrosion. Whether you’re specifying it for industrial equipment, fencing, or architectural use, it delivers performance that justifies its cost over time. With multiple mesh sizes, wire diameters, and surface finishes, it can be customized to fit virtually any application.