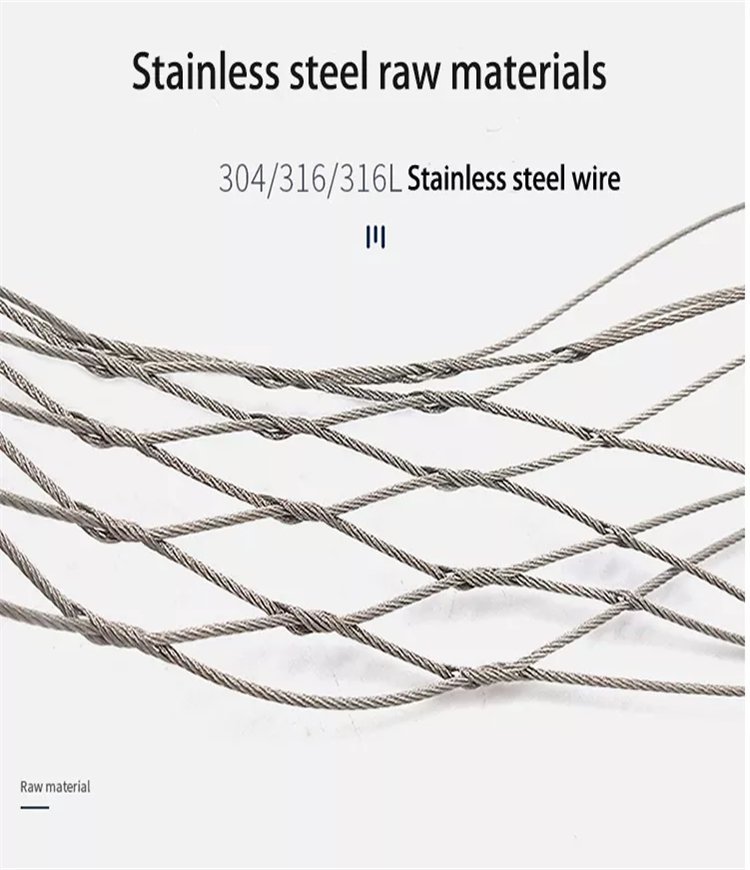

In modern construction, stainless steel Cable Netting shines for its versatility, strength, and looks. It’s made from top-notch AISI 304 and AISI 316L stainless steel. These materials are famous for their superior chemical makeup.

Stainless steel cable netting serves many purposes in construction and design. People use it for:

- Safety Barriers: It protects people in high places like bridges and towers.

- Façade Cladding: Buildings wear it as a stylish outer layer.

- Animal Enclosures: Zoos use it to make safe, open spaces for animals.

- Green Walls: It supports climbing plants on buildings and fences.

- Suspension Bridges: It adds strength and safety to the structure.

- Staircases and Balustrades: It provides a secure, see-through barrier.

- Art Installations: Artists choose it for large, durable outdoor works.

- Aviaries: It creates large, airy homes for birds.

- Fall Protection: It stops people from falling at construction sites.

- Decorative Elements: It adds a modern touch to interiors and exteriors.

Specifications Stainless Steel Cable Netting

| Cable Diameter (inch) |

Cable Diameter (mm) |

Mesh Opening Size (inch) |

Mesh Opening Size (mm) |

Nominal Break (lbs.) |

| 1/8 |

3.2 |

2×2 |

51×51 |

1600 |

| 3/32 |

2.4 |

3×3 |

76×76 |

920 |

| 3/32 |

2.4 |

2×2 |

51×51 |

920 |

| 5/64 |

2.0 |

2×2 |

51×51 |

676 |

| 5/64 |

2.0 |

1-1/2×1-1/2 |

38×38 |

676 |

| 1/16 |

1.6 |

1-1/2×1-1/2 |

38×38 |

480 |

| 1/16 |

1.6 |

1×1 |

25.4×25.4 |

480 |

| 3/64 |

1.2 |

1-1/2×1-1/2 |

38×38 |

270 |

| 3/64 |

1.2 |

1×1 |

25.4×25.4 |

270 |

The Magic of AISI 304 and AISI 316L

These steel grades are well-regarded for their impressive corrosion resistance, attributed to the specific chemical compositions. AISI 304 consists of approximately 18% chromium and 8% nickel, offering excellent formability and ease of cleaning, pivotal for structures exposed to environmental factors.

On the other hand, AISI 316L has similar chromium content but adds 2-3% molybdenum to the mix. This addition enhances its resistance to chloride corrosion, making it an ideal choice for coastal or high saline environments.

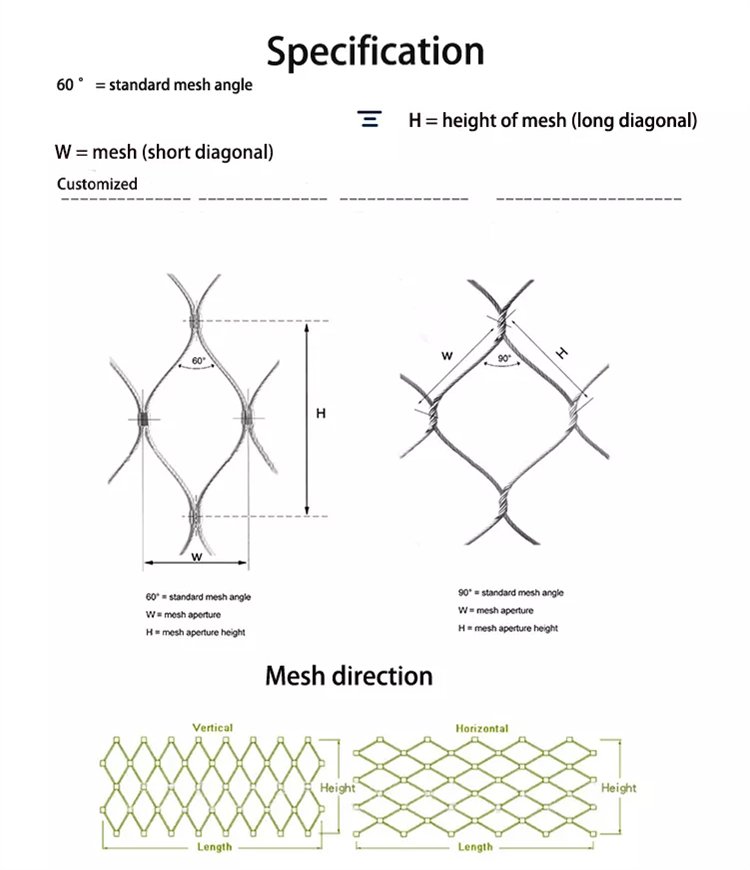

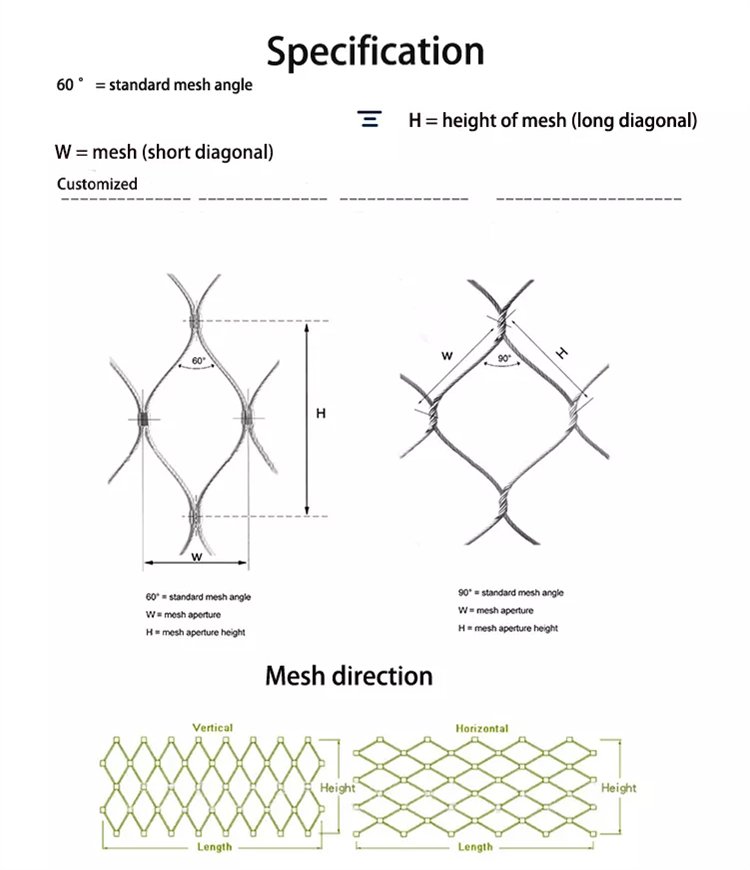

Mastering the Art of Mesh Direction

The secret to why stainless steel cable netting is so strong and flexible comes down to its design. You often find it made in patterns called 7×7 or 7×19. This means seven wire ropes are twisted together in a unique way, making the netting both strong and able to bend. This design lets the netting handle a lot of pressure and keeps things very safe.

When talking about the size of the netting, we look at three things: how wide the openings are (OW), how tall they are (OH), and how thick the cables are (d). To ensure the netting is super strong and stable, it keeps a 60-degree angle at the top and bottom of each diamond shape when stretched out.

Unmatched Benefits of Stainless Steel Cable Netting

Beyond the technical jargon, stainless steel cable netting offers several real-world advantages that make it a go-to choice for various applications, particularly in bridge construction.

Safety First: The netting’s high-strength material ensures the safety of vehicles and personnel, effectively preventing falls from high altitudes or suicide attempts.

Visual Appeal: The stainless steel rope mesh contributes a sleek, modern aesthetic to the suspension bridge, enhancing its status as a magnificent landscape.

Extended Lifespan: With the rust and corrosion resistance of quality stainless steel, the netting promises an extended service life, ensuring a worthwhile investment.

Flexibility: Its flexible structure minimizes visual intrusion while preserving the original design of structures like the Golden Gate Bridge.

Secure and Reliable Packaging

To ensure the integrity of the stainless steel cable netting during transport and storage, it is securely packaged. This process protects the netting from any damage or contaminants that could compromise its quality or performance.

To sum up, stainless steel cable netting combines strength, flexibility, and beauty. It’s perfect for today’s building needs. Using AISI 304 and AISI 316L steel, it ensures safety, lasts long, and looks great. It fits well for suspension bridges and more.