- 規格

不鏽鋼電纜網是一種用途廣泛的創新和多功能材料. 它的靈活性, 耐久性, 和美學吸引力使其成為許多行業的熱門選擇, 包括建築, 動物園, 和建築. 您可以根據人們的製作方式將不鏽鋼電纜網分為兩種主要類型: 套圈繩網和交織鋼絲繩網. 也, 這些網格的表面處理選項分為兩類: 無表面處理和黑色氧化處理. 本文將探討這些分類之間的差異及其獨特的優勢和應用.

不鏽鋼電纜網是一種堅固而靈活的材料,可用於許多不同的專案. 以下是一些常見的應用:

- 動物園圍欄: 它非常適合在動物園中製作籠子和圍欄,因為它經久耐用,讓遊客可以清楚地看到動物.

- 鳥籠網: 許多人用它來建造鳥舍,因為它對鳥類很安全, 不生鏽, 並允許充足的光線和空氣通過.

- 安全圍欄: 它適用於橋樑上的安全圍欄, 陽臺, 和樓梯,因為它很堅固,不會擋住視線.

- 建築設計: 建築師選擇這種網布用於建築立面或裝飾特徵,因為它看起來很現代並且可以應對惡劣的天氣.

- 綠化牆: 它支撐著綠化牆壁上的攀援植物, 幫助創建美化城市空間的垂直花園.

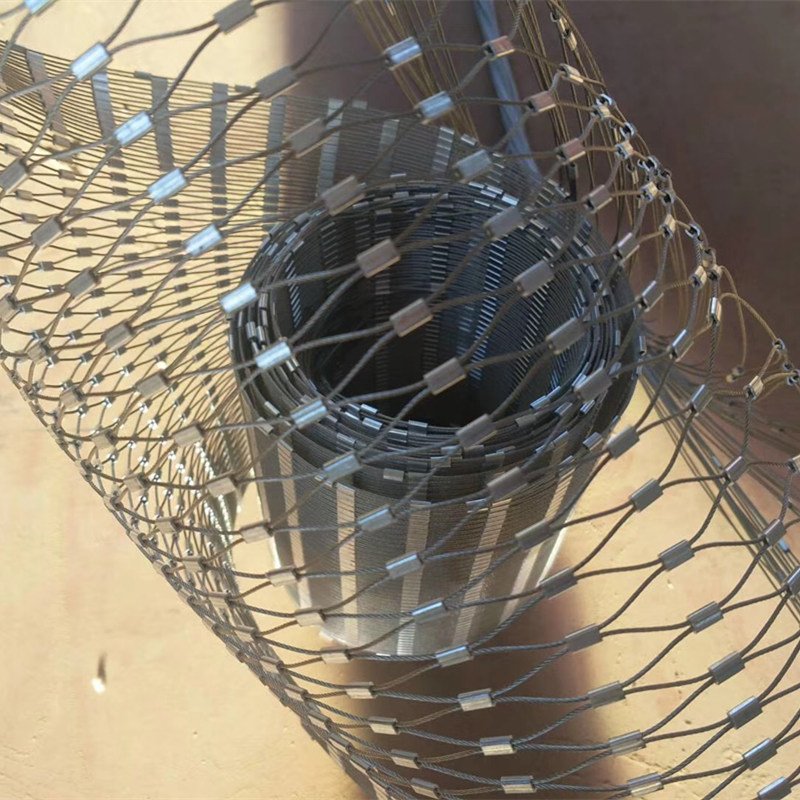

套圈繩不鏽鋼電纜網

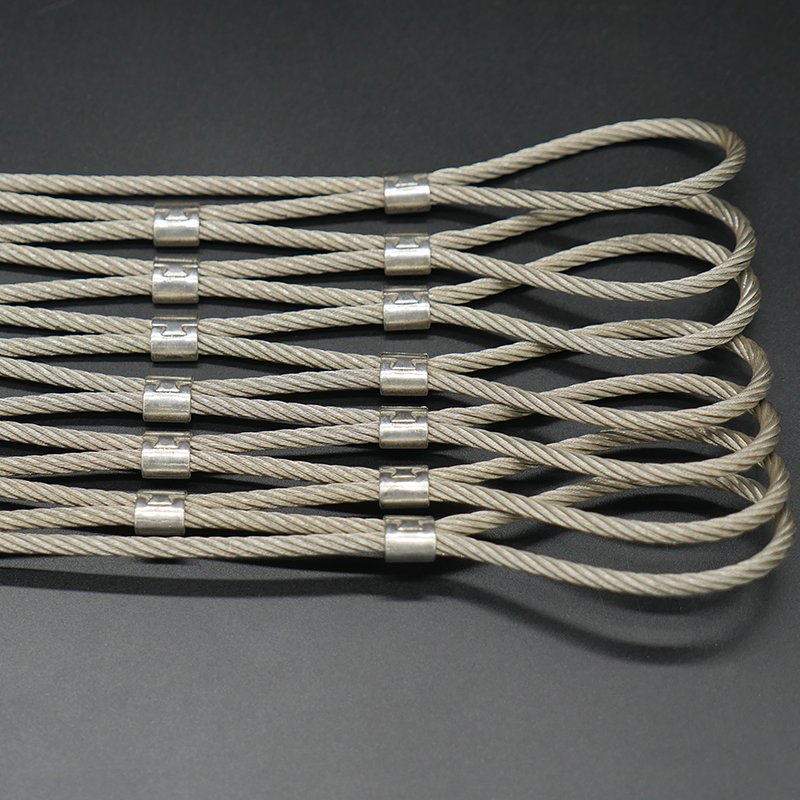

套圈繩網是通過將不鏽鋼絲繩與一系列套圈連接而成的, 它們是壓接或鍛造到繩索上以將它們固定在一起的金屬套管或管子. 這種類型的網孔的特點是其強度, 穩定, 和靈活的結構, 使其適用於各種應用.

交織鋼絲繩不鏽鋼電纜網

交織鋼絲繩網是通過將不鏽鋼鋼絲繩編織在一起形成柔性製成的, 但網孔堅固. 此方法會生成一個具有唯一, 兼具強度和柔韌性的菱形圖案.

優勢:

高靈活性: 交織結構使網眼易於彎曲和成型,而不會失去強度, 使其適用於多種應用.

抗衝擊性: 菱形花紋提供出色的抗衝擊性, 非常適合容易受到撞擊或碰撞的區域.

定製: 像套圈繩網, 您可以根據特定的設計需求定製交織鋼絲繩網.

輕: 編織過程使網眼更輕, 簡化了操作和安裝.

表面處理

無表面處理: 不鏽鋼電纜網,未經任何表面處理,保持其自然的金屬外觀, 閃耀明亮且耐腐蝕,適合室內和室外使用.

黑色氧化物處理: 工人塗黑色氧化物, 化學轉化塗層, 到不鏽鋼電纜網,以增強耐腐蝕性和啞光黑色飾面. 這種治療可以提高審美吸引力並減少眩光, 非常適合需要非反射表面的應用.

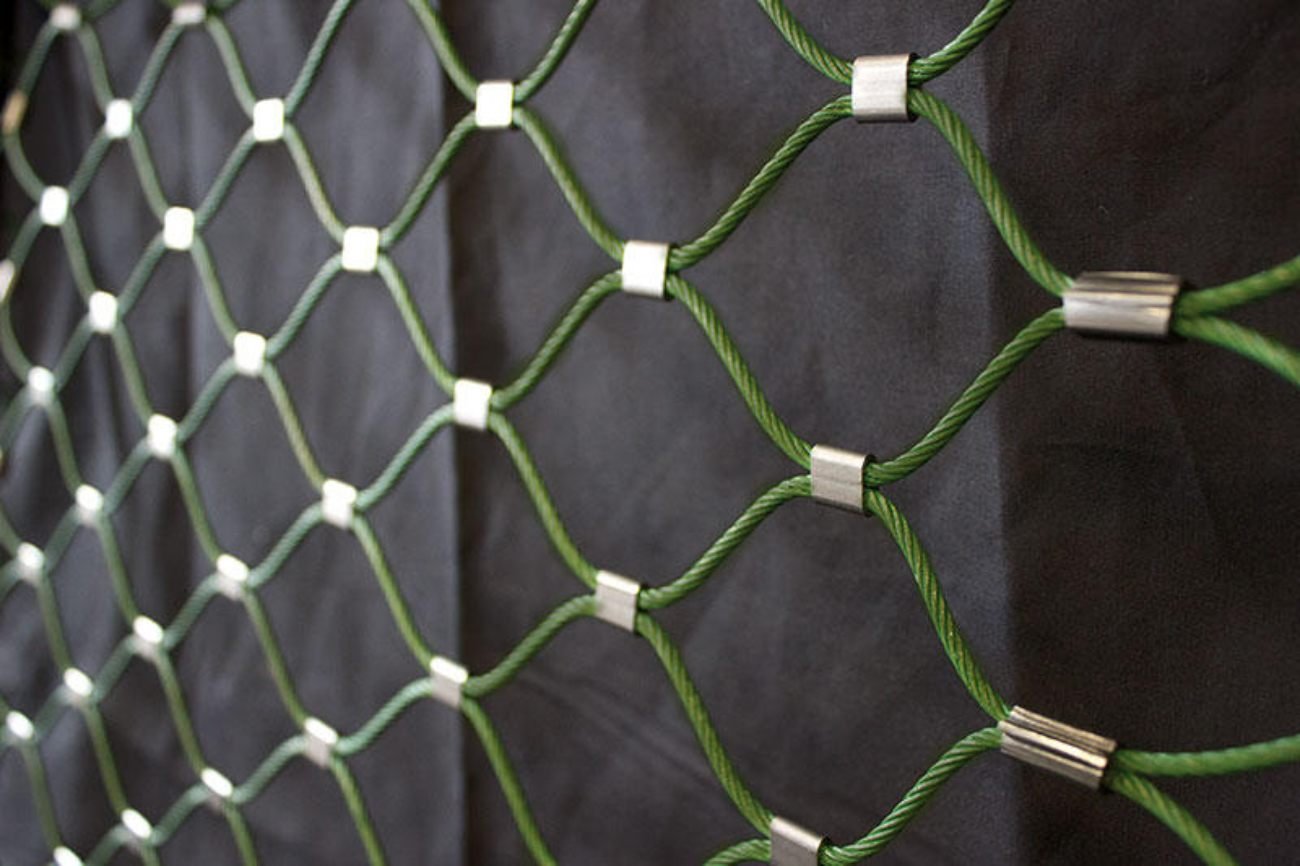

乙烯基塗層處理: 在不鏽鋼電纜網上塗覆乙烯基塗層可增加防腐蝕保護, 磨損, 和紫外線損傷. 它還會添加顏色並增強網格的外觀, 使其適用於各種裝飾和功能用途. 乙烯基塗層網的光滑表面易於清潔和維護, 室內和室外環境的理想選擇.

不鏽鋼電纜網規格

| 法典 | 繩索結構 | 繩索直徑 | 孔徑 | 最小斷裂載荷 (磅) |

|---|---|---|---|---|

| BMZOO 公司-01 | 7 × 7 | 1/8″ (3.2毫米) | 2″ 2 個″ (51 × 51 毫米) | 1600 |

| BMZOO 公司-02 | 7 × 7 | 3/32″ (2.4毫米) | 4″ 4 倍″ (102 × 102 毫米) | 920 |

| BMZOO 公司-03 | 7 × 7 | 3/32″ (2.4毫米) | 3″ 3 倍″ (76 × 76 毫米) | 920 |

| BMZOO 公司-04 | 7 × 7 | 3/32″ (2.4毫米) | 2″ 2 個″ (51 × 51 毫米) | 920 |

| BMZOO 公司-05 | 7 × 7 | 5/64″ (2.0毫米) | 3″ 3 倍″ (76 × 76 毫米) | 676 |

| BMZOO 公司-06 | 7 × 7 | 5/64″ (2.0毫米) | 2″ 2 個″ (51 × 51 毫米) | 676 |

| BMZOO 公司-07 | 7 × 7 | 5/64″ (2.0毫米) | 1.5″ 1.5 倍″ (38 × 38 毫米) | 676 |

| BMZOO 公司-08 | 7 × 7 | 1/16″ (1.6毫米) | 3″ 3 倍″ (76 × 76 毫米) | 504 |

| BMZOO 公司-09 | 7 × 7 | 1/16″ (1.6毫米) | 2″ 2 個″ (51 × 51 毫米) | 504 |

| BMZOO-10 | 7 × 7 | 1/16″ (1.6毫米) | 1.5″ 1.5 倍″ (38 × 38 毫米) | 504 |

| BMZOO-11 | 7 × 7 | 1/16″ (1.6毫米) | 1″ 1 倍″ (25 × 25 毫米) | 504 |

| BMZOO-12 | 7 × 7 | 3/64″ (1.2毫米) | 2″ 2 個″ (51 × 51 毫米) | 306 |

| BMZOO-13 | 7 × 7 | 3/64″ (1.2毫米) | 1.5″ 1.5 倍″ (38 × 38 毫米) | 306 |

| BMZOO-14 | 7 × 7 | 3/64″ (1.2毫米) | 1″ 1 倍″ (25 × 25 毫米) | 306 |

| BMZOO-15 | 7 × 7 | 3/64″ (1.2毫米) | 4/5″ (4/5 倍)″ (20 × | 306 |

結論

為專案選擇不鏽鋼電纜網時, 考慮最適合您需求的生產方法和表面處理. 套圈繩網和交織鋼絲繩網在強度方面均具有獨特的優勢, 靈活性, 和外觀. 此外, 在無表面處理和黑色氧化物處理之間進行選擇會影響網片的美觀性, 耐腐蝕性, 和減少眩光. 瞭解這些區別有助於設計師和工程師在為他們的項目選擇理想的不鏽鋼電纜網時做出明智的決策.