» 不銹鋼電纜網 » Guide to Stainless Steel Cable Mesh

- 規格

Stainless steel cable mesh is an innovative and versatile material with a wide range of uses. 其靈活性, 耐久性, and aesthetic appeal make it a popular choice across many industries, including architecture, 動物園, and construction. You can classify stainless steel cable mesh into two main types based on how people make it: ferrule rope mesh and inter-woven wire rope mesh. Also, the surface treatment options for these meshes fall into two categories: no surface treatment and Black Oxide treatment. This article will explore the differences between these classifications and their unique benefits and applications.

Stainless steel cable mesh is a strong and flexible material that’s useful for many different projects. Here are some common applications:

- Zoo Enclosures: It’s perfect for creating cages and enclosures in zoos because it is durable and lets visitors see the animals clearly.

- 鳥籠網: Many use it to build aviaries because it is safe for birds, doesn’t rust, and allows plenty of light and air through.

- Safety Fences: It works well for safety fences on bridges, 陽台, and staircases because it is strong and doesn’t block the view.

- Architectural Designs: Architects choose this mesh for building facades or decorative features because it looks modern and can handle harsh weather.

- 綠牆: It supports climbing plants on green walls, helping to create vertical gardens that beautify urban spaces.

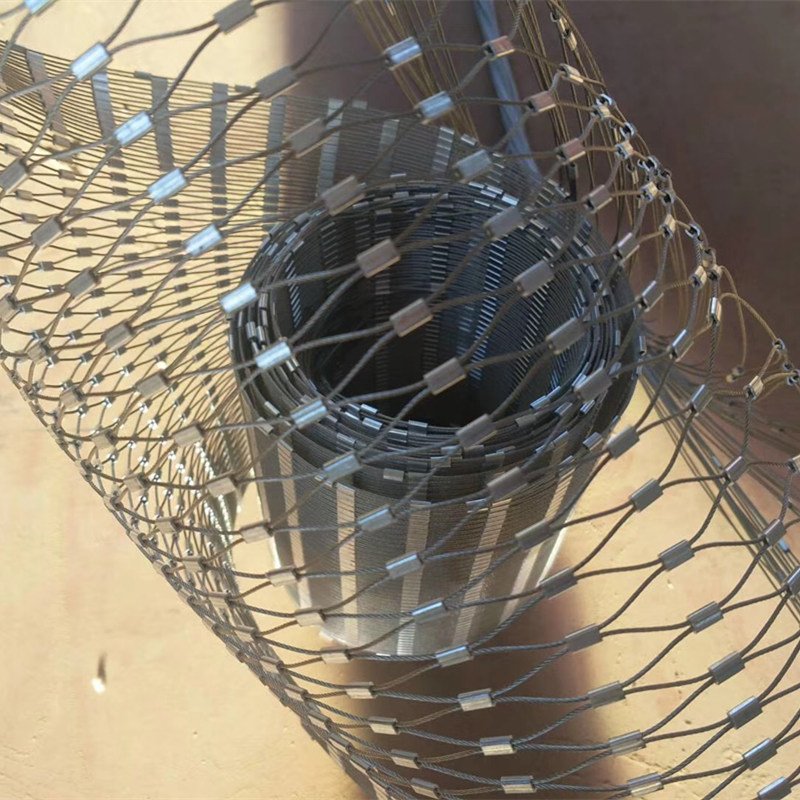

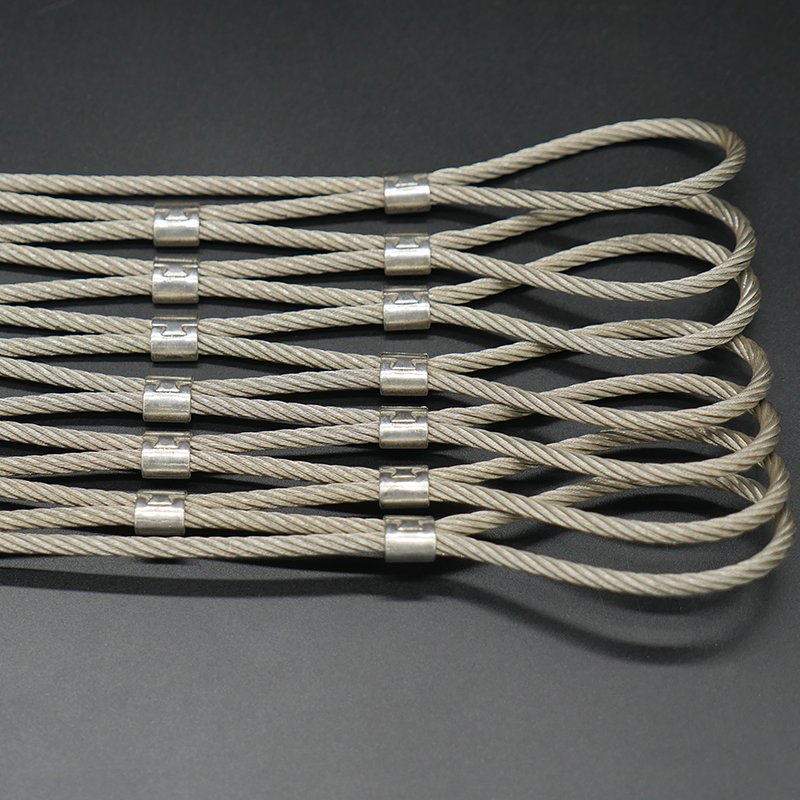

Ferrule Rope Stainless Steel Cable Mesh

Ferrule rope mesh is created by connecting stainless steel wire ropes with a series of ferrules, which are metal sleeves or tubes that are crimped or swaged onto the ropes to hold them together. This type of mesh is characterized by its strong, stable, and flexible structure, making it suitable for use in a variety of applications.

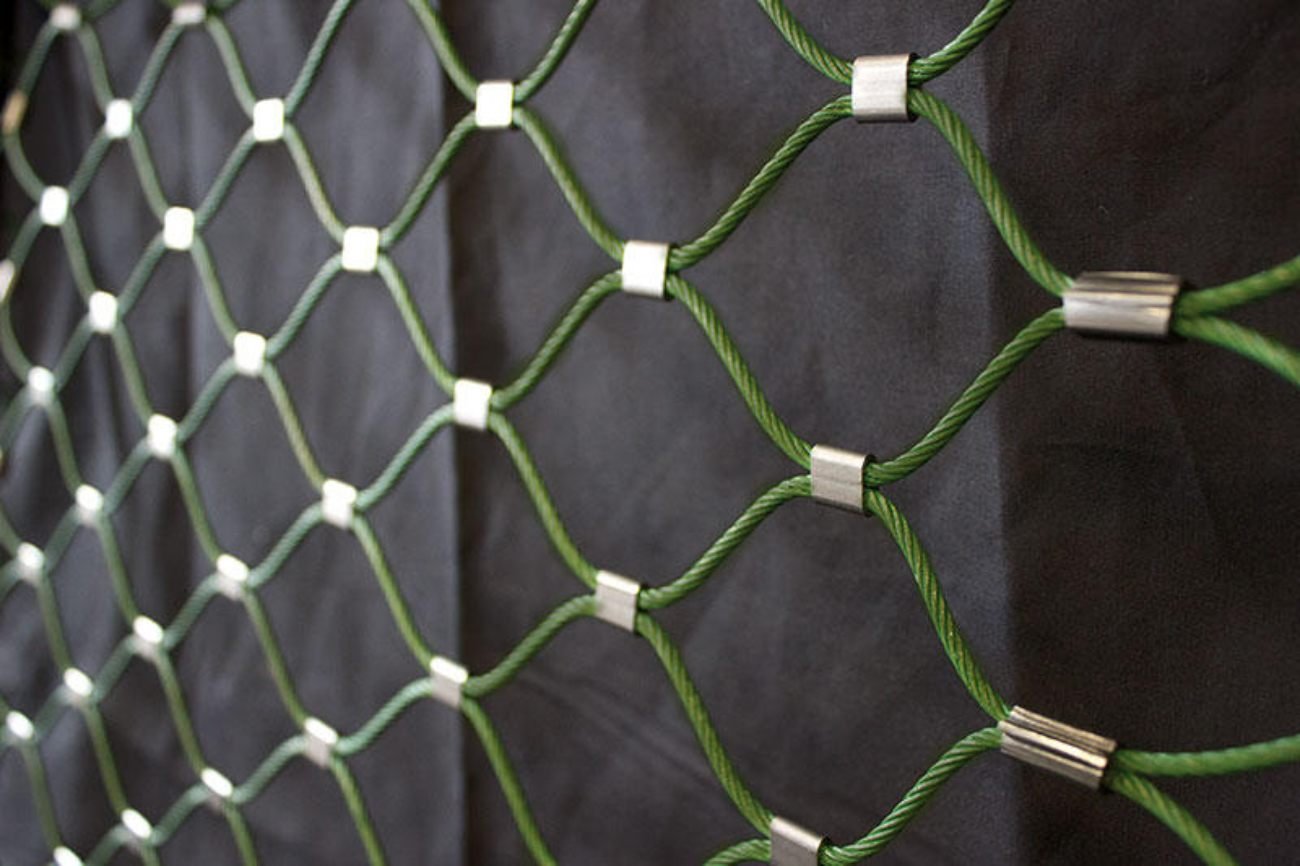

Inter-woven Wire Rope stainless steel cable Mesh

Inter-woven wire rope mesh is made by weaving stainless steel wire ropes together to form a flexible, yet strong mesh. This method produces a mesh with a unique, diamond-shaped pattern that provides both strength and flexibility.

優勢:

High flexibility: The inter-woven structure lets the mesh bend and shape easily without losing strength, making it suitable for many applications.

Impact resistance: The diamond-shaped pattern offers excellent impact resistance, ideal for areas prone to impacts or collisions.

定製: Like ferrule rope mesh, 你可以根據具體設計需求訂造交織鋼索網.

輕: 編織過程令網體重量輕, 從而簡化搬運和安裝.

表面處理

無表面處理: 不經任何表面處理的不銹鋼鋼索網保持其自然金屬外觀, 閃亮耐用,可抗室內及室外的腐蝕.

黑色氧化處理: 工人會對不銹鋼鋼索網施加黑色氧化劑, 這是一種化學轉化塗層, 增強耐腐蝕能力及呈啞光黑色效果. 此處理提升美觀並減少眩光, 非常適合需要無反光表面的應用.

乙烯基塗層處理: 在不銹鋼鋼索網上施加乙烯基塗層可提供防腐蝕, 耐磨損, 及防紫外線保護. It also adds color and enhances the mesh’s appearance, making it suitable for various decorative and functional uses. The smooth surface of the vinyl-coated mesh is easy to clean and maintain, ideal for both indoor and outdoor settings.

Specifications of Stainless Steel Cable Mesh

| 法典 | 繩索結構 | 繩索直徑 | 孔徑 | Min Breaking Load (磅) |

|---|---|---|---|---|

| BMZOO-01 | 7 × 7 | 1/8″ (3.2毫米) | 2″ 2個″ (51 × 51mm) | 1600 |

| BMZOO-02 | 7 × 7 | 3/32″ (2.4毫米) | 4″ 4倍″ (102 × 102mm) | 920 |

| BMZOO-03 | 7 × 7 | 3/32″ (2.4毫米) | 3″ 3倍″ (76 × 76mm) | 920 |

| BMZOO-04 | 7 × 7 | 3/32″ (2.4毫米) | 2″ 2個″ (51 × 51mm) | 920 |

| BMZOO-05 | 7 × 7 | 5/64″ (2.0毫米) | 3″ 3倍″ (76 × 76mm) | 676 |

| BMZOO-06 | 7 × 7 | 5/64″ (2.0毫米) | 2″ 2個″ (51 × 51mm) | 676 |

| BMZOO-07 | 7 × 7 | 5/64″ (2.0毫米) | 1.5″ 1.5倍″ (38 × 38mm) | 676 |

| BMZOO-08 | 7 × 7 | 1/16″ (1.6毫米) | 3″ 3倍″ (76 × 76mm) | 504 |

| BMZOO-09 | 7 × 7 | 1/16″ (1.6毫米) | 2″ 2個″ (51 × 51mm) | 504 |

| BMZOO-10 | 7 × 7 | 1/16″ (1.6毫米) | 1.5″ 1.5倍″ (38 × 38mm) | 504 |

| BMZOO-11 | 7 × 7 | 1/16″ (1.6毫米) | 1″ 1倍″ (25 × 25mm) | 504 |

| BMZOO-12 | 7 × 7 | 3/64″ (1.2毫米) | 2″ 2個″ (51 × 51mm) | 306 |

| BMZOO-13 | 7 × 7 | 3/64″ (1.2毫米) | 1.5″ 1.5倍″ (38 × 38mm) | 306 |

| BMZOO-14 | 7 × 7 | 3/64″ (1.2毫米) | 1″ 1倍″ (25 × 25mm) | 306 |

| BMZOO-15 | 7 × 7 | 3/64″ (1.2毫米) | 4/5″ x 4/5″ (20 × | 306 |

結論

When selecting stainless steel cable mesh for a project, consider the production method and surface treatment that best suit your needs. Ferrule rope mesh and inter-woven wire rope mesh each offer unique advantages in strength, 靈活性, 以及外觀. 此外, choosing between no surface treatment and black oxide treatment affects the mesh’s aesthetics, 耐腐蝕性, and glare reduction. Understanding these distinctions helps designers and engineers make informed decisions when choosing the ideal stainless steel cable mesh for their projects.