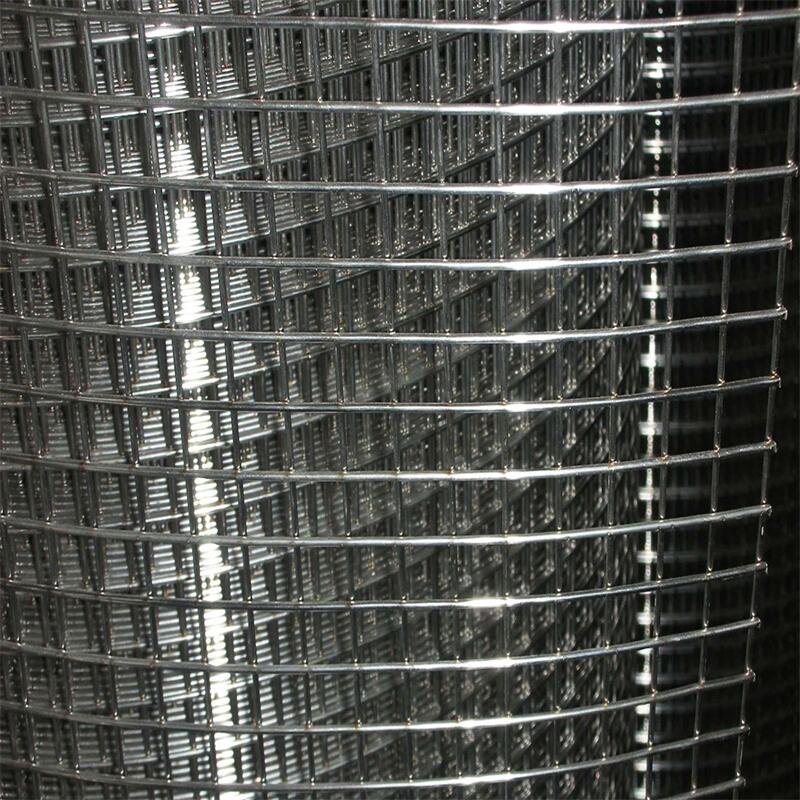

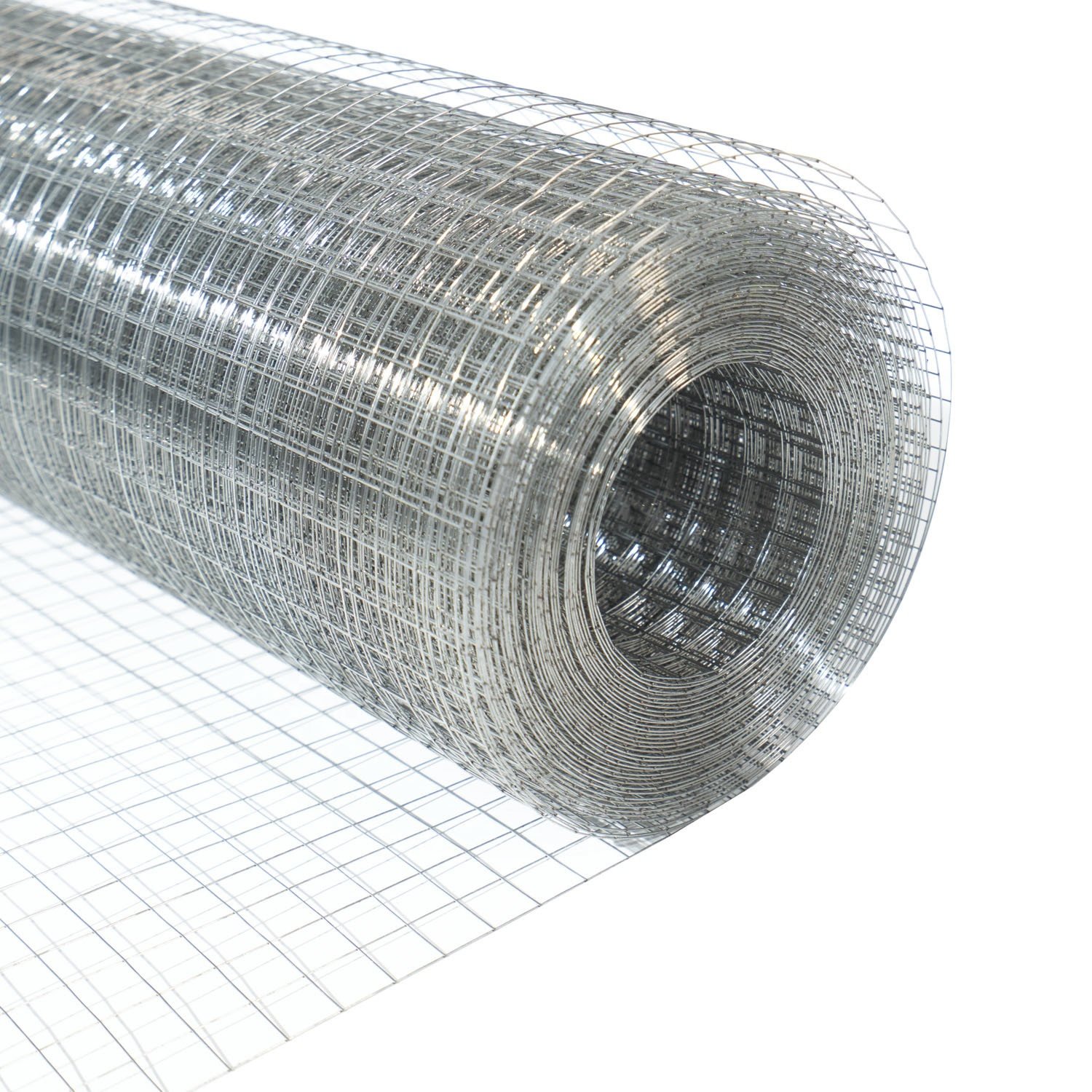

Welded Wire Mesh: A Sturdy and Durable Option

Welded wire mesh, also known as welded wire or welded mesh, is a structure made by welding steel wires together at intersections. This process creates a strong, lasting, and rust-resistant material perfect for various applications like zoo enclosures. The mesh undergoes galvanization after welding, with two available methods: hot-dipped (hot galvanized) and cold (electric) galvanized. This galvanization process adds an extra layer of protection against corrosion and weathering, making it great for outdoor use.

PVC Coated Welded Wire Mesh: Enhanced Protection and Aesthetics

A more advanced option for zoo enclosures is PVC coated welded metal mesh. Manufacturers make this from high-quality, low carbon steel wire mesh, which first undergoes a galvanization process before a PVC or PE powder coating. This coating provides an even, strong, and adherent layer with a bright luster, which not only boosts its anti-corrosive properties but also ensures long-lasting material.

One of the key advantages of PVC coated welded metal mesh is its customizability in various colors to meet specific requirements. This allows zoos to create aesthetically pleasing enclosures that blend with the surrounding environment and provide a more natural habitat for the animals.

Versatility and Customization

Welded wire mesh comes in various widths and lengths, such as 3′, 4′, 5′, 6′, and 7′. This lets zoos choose the most appropriate size for their enclosures, ensuring optimal safety and visibility. Moreover, manufacturers can customize other widths and lengths at the buyer’s request, offering even greater flexibility in designing enclosures that cater to the unique needs of each species.