Stainless Steel Cable Nets, made of top-tier AISI 304 and AISI 316L stainless steel, are popular choices in various industries, from construction to decoration and beyond. Besides being visually appealing, these nets offer numerous practical advantages that make them stand out from the rest.

Choosing between knotted and ferrule stainless steel cable nets involves considering the specific needs of your project, including aesthetic preferences, load requirements, and environmental conditions. Both types offer high strength, durability, and flexibility, but they cater to different applications and preferences. Here’s a guide to help you decide which is the best fit for your needs:

Understanding the Differences

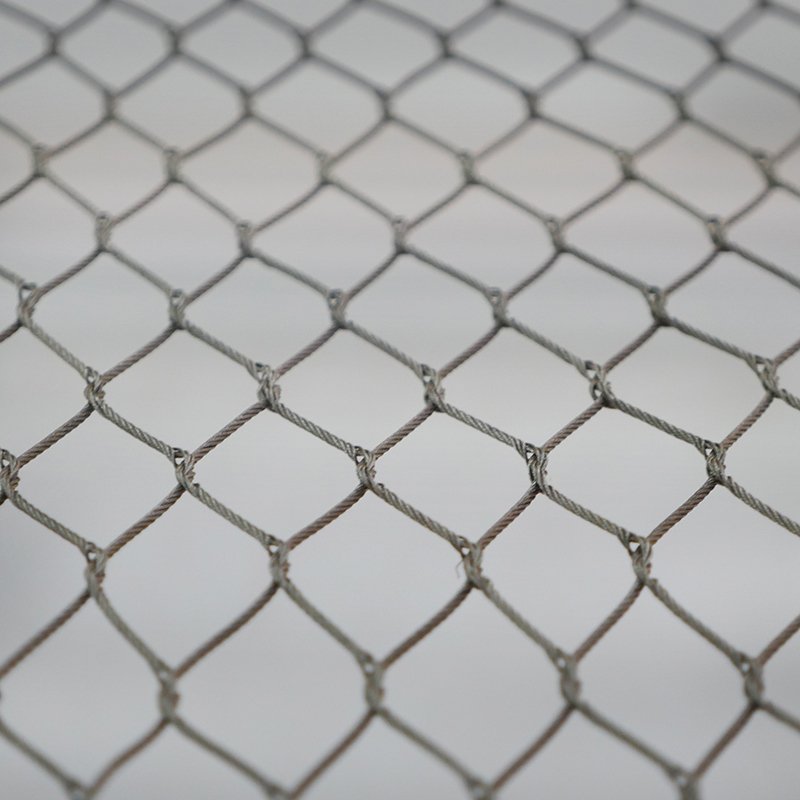

Knotted Stainless Steel Cable Nets: Workers tie the cables together where they cross. This old way of making nets makes them very strong and able to carry heavy weights. People like knotted nets because you can see through them easily. They don’t block your view much, so they’re great for places where you want to keep things visible.

Ferrule Stainless Steel Cable Nets: For ferrule nets, workers use metal sleeves, called ferrules, to join the cables where they cross. This makes the net look neat and even, giving it a modern look that fits well with new buildings. The ferrules might be the same kind of stainless steel as the cables, or something different, like tinned copper, to make them look nicer.

Factors to Consider

Aesthetic Preferences: If visual transparency and minimal impact are your priority, knotted nets might be the way to go. For sleek, uniform lines that complement modern architecture, ferrule nets offer an elegant solution.

Load Requirements: Both knotted and ferrule nets are strong, but the specific load requirements of your project might sway your decision. Knotted nets, with their direct cable-to-cable connections, are often perceived as slightly stronger, making them suitable for heavier loads.

Environmental Conditions: Stainless steel is inherently resistant to corrosion and environmental wear, but the choice between knotted and ferrule nets can be influenced by specific environmental conditions. Ferrule nets, especially those with stainless steel ferrules, might offer better long-term durability in highly corrosive environments, such as coastal areas.

Installation and Maintenance: Consider the installation process and long-term maintenance. Knotted nets can be slightly more forgiving during installation, as there’s a bit more flexibility in the tensioning process. Ferrule nets require precise installation to maintain their aesthetic appeal. Maintenance for both types is relatively low, but any damaged section in a ferrule net might require replacing a larger segment compared to a knotted net.

AISI 304 and AISI 316L Stainless Steel: An Overview

Stainless Steel Cable Nets are crafted from high-quality stainless steel. There are two primary types used – AISI 304 and AISI 316L. AISI 304 is well-known for its excellent formability and weldability, making it a perfect choice for a variety of applications. AISI 316L, on the other hand, boasts superior corrosion resistance, particularly against chlorides and other industrial solvents.

Specifications Stainless Steel Cable Net

Stainless Steel Cable Nets provide a range of benefits that give them an edge over other materials. Here are a few:

- Unmatched Flexibility: These nets can bend and fold to meet your specific requirements, offering a high degree of adaptability.

- Remarkable Durability: They are resistant to impact, rain, snow, and hurricanes, ensuring long-term performance.

- Strong and Tough: The high-strength design of these nets allows them to withstand significant loads.

- Long Lifespan: With a service life of over 30 years, these nets are a cost-effective solution for a variety of applications.

Applications of Stainless Steel Cable Nets

From zoos and playgrounds to architectural projects, Stainless Steel Cable Nets are versatile enough to meet diverse needs. These nets are perfect for creating animal enclosures, playground fences, safety nets, and decorative walls. They also serve as effective protective devices in acrobatic shows and as architectural safety nets.

Packing and Delivery

Our Stainless Steel Cable Nets are securely packed with plastic foam inside and wooden cases outside. We ensure timely delivery through FedEx, DHL, UPS, and EMS. Payment options include T/T, Paypal, L/C, and Western Union.

Conclusion

In conclusion, stainless steel cable mesh, made from AISI 304 and AISI 316L, are durable, versatile, and aesthetically pleasing. They offer a host of advantages that make them a valuable asset in a variety of fields. Whether you need a net for your zoo or a safety net for your building, these nets are sure to meet and exceed your expectations. From providing safety barriers and animal enclosures to enhancing architectural designs, their strength, resistance to corrosion and UV, and variety of specifications make them an ideal choice for projects requiring long-lasting reliability and visual appeal.