» Blog » 316 Stainless Steel: A Rust-Resistant Wonder Metal

316 Stainless Steel: A Rust-Resistant Wonder Metal

March 27, 2024

316 stainless steel is a strong, rust-resistant metal used in many areas. It’s made of elements like chromium, nickel, molybdenum, and more. This blend makes it especially good at resisting tiny holes, cracks, and salty conditions. In this piece, we’ll take a closer look at what makes this metal special, where it’s used, and why it’s so helpful.

Exceptional Durability and Strength

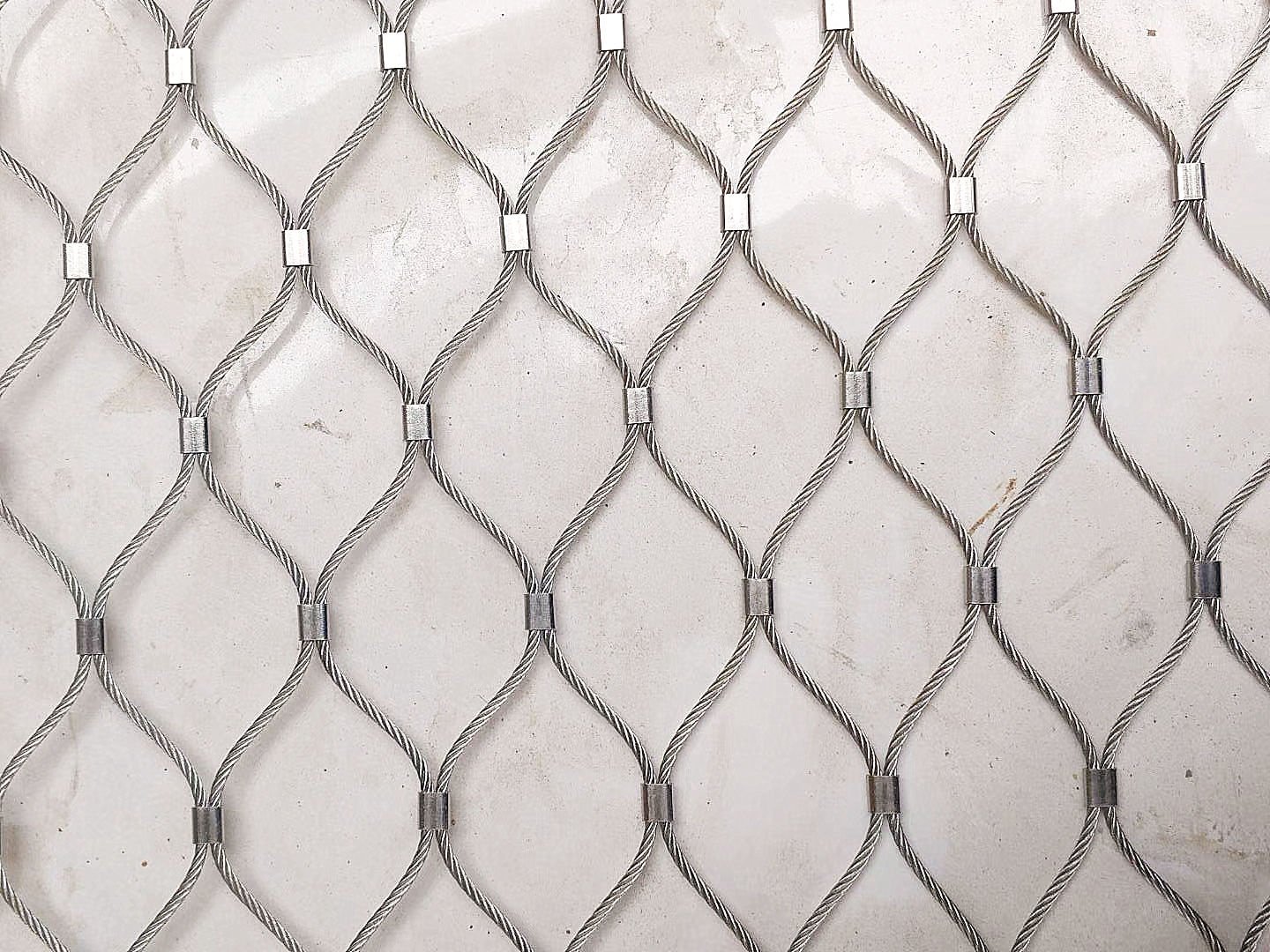

316 stainless steel, known for its exceptional strength, offers the perfect balance between durability and flexibility. This quality is essential for zoo mesh applications, where the enclosure must withstand the physical strength of animals, from the gentle push of a bird to the powerful impact of a large mammal. The robust nature of 316 stainless steel ensures that enclosures remain intact and secure, providing a safe environment for both the inhabitants and the visitors.

Superior Corrosion Resistance

One of the most significant advantages of 316 stainless steel is its enhanced corrosion resistance, especially compared to its counterpart, 304 stainless steel. The addition of molybdenum in 316 stainless steel gives it the ability to resist corrosion in harsh environments, including those exposed to seawater and chlorine. Zoos, often located in varied climates and requiring frequent cleaning, need materials that can withstand these conditions without deteriorating. 316 stainless steel’s corrosion resistance ensures a longer lifespan for zoo meshes, reducing the need for frequent replacements and maintenance.

Safety and Non-Toxicity

Safety is paramount in zoo environments, not just for the visitors but also for the animal inhabitants. 316 stainless steel is a non-toxic material, free from coatings or finishes that could potentially harm animals if ingested. Its smooth surface also minimizes the risk of injuries for animals that might come into contact with the mesh. For birds and smaller creatures that might climb or perch on the enclosures, the material’s safety ensures that they can explore without the risk of cuts or other injuries.

Aesthetic Appeal

Beyond its functional benefits, 316 stainless steel also offers aesthetic advantages. Its sleek, modern appearance integrates seamlessly into various zoo environments, from tropical bird aviaries to arctic penguin exhibits. The material’s natural sheen enhances visibility, ensuring that visitors have a clear and unobstructed view of the animals. Moreover, its ability to maintain its appearance over time, resisting stains and discoloration, keeps zoo enclosures looking pristine and inviting.

Eco-Friendly

In an age where environmental sustainability is increasingly important, choosing materials that have minimal environmental impact is crucial. 316 stainless steel is 100% recyclable, reducing its ecological footprint. Its long lifespan and durability mean that less material needs to be produced and disposed of over time, contributing to conservation efforts and the sustainable operation of zoos.

Applications

316 stainless steel is super useful. One of the big places you’ll find it is in zoos. They use it to make the mesh for animal enclosures. This zoo mesh is strong and doesn’t rust, so it keeps the animals safe and lasts a long time.

Another place you’ll see stainless steel is in making rope nets. These ropes are super tough and resist rust. They’re perfect for uses where you need strength and durability, like in construction or in heavy-duty cargo nets.

This just shows how versatile 316 stainless steel is. Whether it’s keeping lions safe in a zoo or helping to lift heavy objects, 316L stainless steel gets the job done.

Technical Information

| Property | Value |

|---|---|

| Chemical Composition | Fe, <0.03% C, 16-18.5% Cr, 10-14% Ni, |

| 2-3% Mo, <2% Mn, <1% Si, <0.045% P, <0.03% S | |

| Tensile Strength | Minimum 515 MPa |

| Yield Strength (0.2% Proof) | Minimum 205 MPa |

| Elongation | Minimum 40% in 50 mm |

| Hardness (Rockwell B) | Maximum 95 HR B |

| Density | 8000 kg/m3 |

| Elastic Modulus | 193 GPa |

| Coeff. of Thermal Expansion | 15.9 μm/m/°C (0-100 °C) |

| 16.2 μm/m/°C (0-315 °C) | |

| 17.5 μm/m/°C (0-538 °C) | |

| Thermal Conductivity | 16.3 W/m·K (at 100 °C) |

| 21.5 W/m·K (at 500 °C) | |

| Specific Heat (0-100 °C) | 500 J/kg·K |

| Electrical Resistivity | 740 nΩ·m (at 20 °C) |

Note: The values provided are approximate and may vary depending on specific product forms and manufacturing processes.

Corrosion Resistance and Makeup:

Grade 316 stainless steel is made of special elements that protect it from rust. It has between 16% and 18.5% chromium that helps form a protective layer on its surface, making it hard for rust to form. Also, it has 2-3% molybdenum that makes it tough against tiny cracks and holes, particularly when in places with lots of salt (chlorides). This type of steel is better than Grade 304 stainless steel when it comes to fighting off rust. This makes it great for heavy-duty jobs.

Strength and Long-lasting:

Grade 316 stainless steel is strong and long-lasting. It can withstand a lot of pulling force, up to 515 MPa, and it can handle a stress level up to 205 MPa before it starts to permanently deform. This steel is very strong and keeps its strength even in very cold temperatures. This makes it suitable for many different places and conditions.

Uses:

Grade 316 stainless steel is useful in many areas. In the food-making industry, it’s used a lot for tools and surfaces because it can handle salt and is easy to clean. It’s also used on lab tables, buildings near the sea, boat parts, and devices that control heat. The steel’s ability to handle salt at high temperatures makes it perfect for containers that carry chemicals and parts in vehicles.

Welding and Shaping:

You can weld Grade 316 stainless steel easily. You can do this with or without extra metals. For welding, you use Grade 316 or 316L rods. If you weld large parts, you need to heat them again after welding. This step keeps the metal strong against rust. You can also shape this steel easily. New types, called “Ugima,” let you shape it faster and with less damage to your tools. This improvement makes work more efficient.

Dual Labels and Other Choices:

You can find some Grade 316 stainless steel products with two labels. These meet both the 316 and 316L standards. You often see these labels on plates and pipes. But, these double-labeled products don’t fit the Grade 316H requirements. You need Grade 316H for structures and things that get very hot. Depending on what you need, you could think about other types. These include 316Ti for better heat resistance, 316N for more strength, and 317L or 904L for better resistance to salt.

Summary:

Many industries pick Grade 316 stainless steel because it resists rust, is strong, and you can use it in many ways. You see it in tools for making food, buildings near the sea, containers for chemicals, and devices that manage heat. Understanding what this metal is made of, how strong it is, and where you can use it helps builders and designers make the best use of it. In the end, this leads to products that last a long time and satisfy customers.

Return Policy

Return Policy Stainless Steel Cable Inter-Woven Mesh is the Perfect Choice

Stainless Steel Cable Inter-Woven Mesh is the Perfect Choice Stainless Steel Cable Opened Ferrule Mesh

Stainless Steel Cable Opened Ferrule Mesh Zoo Mesh: Enhancing Safety and Well-being in Zoological Parks

Zoo Mesh: Enhancing Safety and Well-being in Zoological Parks Zoo Mesh: The Key to Safe and Engaging Animal Enclosures

Zoo Mesh: The Key to Safe and Engaging Animal Enclosures