X-Tend Mesh is a flexible and strong stainless steel mesh designed for building projects. It works well for railings, safety barriers, zoo enclosures, and bird cages. This article talks about the features, benefits, and uses of X-Tend Mesh, showing how it matches well with different stainless steel mesh needs.

Product Description:

X-TEND® is made from stainless steel cable mesh and architects often use it for different purposes like railings, safety barriers, and zoo enclosures. It is durable, flexible, and looks great, creating barriers that are almost invisible but very safe and attractive.

Applications:

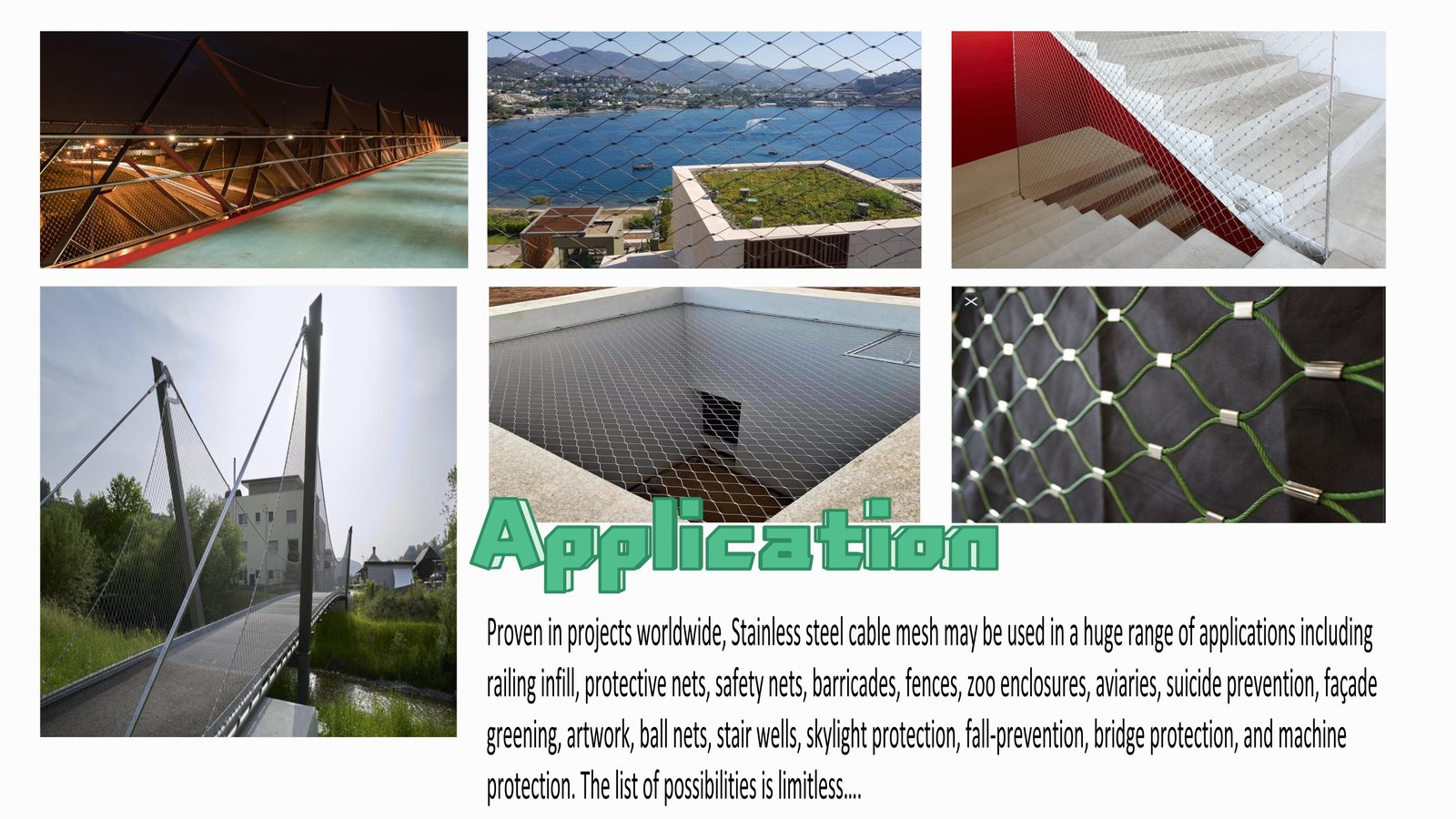

- Versatility: X-Tend Mesh Used in both indoor and outdoor settings for railing fillings, safety barriers, facade claddings, and green walls.

- Special Projects: Suitable for complex zoo installations and free-flight aviaries due to its robust yet flexible design.

Features:

- Materials: Made from high-quality stainless steel, ensuring longevity and resistance to environmental factors.

- Design Flexibility: Available in various mesh sizes and can be tailored to fit unique architectural needs.

- Safety and Design: Mesh design combines safety with visual appeal, able to withstand heavy loads while maintaining transparency.

X-Tend Mesh Installation and Configuration:

- Customizable Installation: Can be adapted to various architectural requirements, offering solutions for complex geometries and large spans without visible seams.

- Installation Support: Carl Stahl Architecture provides full installation services, including planning, static calculations, and onsite assembly, ensuring the mesh integrates perfectly with the architectural design.

Innovations:

- X-TEND Colours: Coloured stainless steel cables available to add visual impact to architectural designs.

- X-LED: An integration option that combines the mesh with LED lighting, creating dynamic lighting effects for both functional and decorative purposes.

X-Tend Mesh System Solutions:

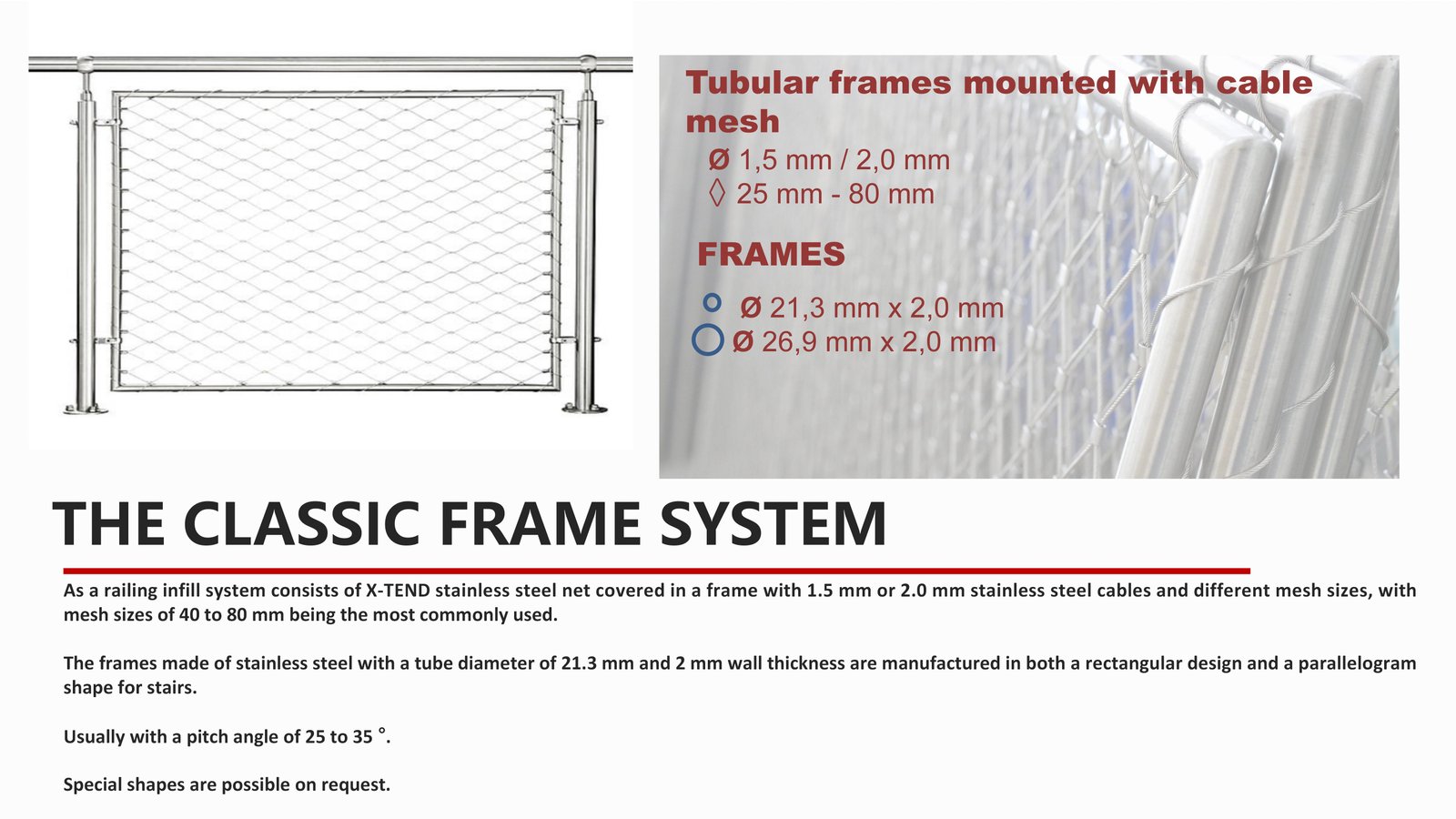

- X-TEND2 and X-TEND3: Pre-assembled frame solutions that simplify installation for specific applications such as balustrades and facades, featuring standardized and custom dimensions to meet various regulatory and design requirements.

Key Advantages:

- Flexible and durable structure

- Customizable widths and lengths

- Suitable for various architectural applications

- Ideal for zoo enclosures and aviaries

- High-quality stainless steel materials

Specifications X-Tend Mesh

| Specification |

Value

x tend mesh

|

| Material |

Stainless steel 304, 304L, 316, 316L etc. |

| Hole Size (Opening) |

Various sizes available |

| Rope Wire Mesh |

1.2mm to 3.2mm |

| Customization |

X-Tend Mesh Widths, lengths, and shapes |

Features and Applications:

- Flexible structure: Suitable for balustrades, railings, facades.

- Customizable: Tailored to specific widths, lengths, shapes.

- Zoo enclosures: Provides safety, visibility for animal habitats.

- High-quality materials: Offers durability, corrosion resistance.

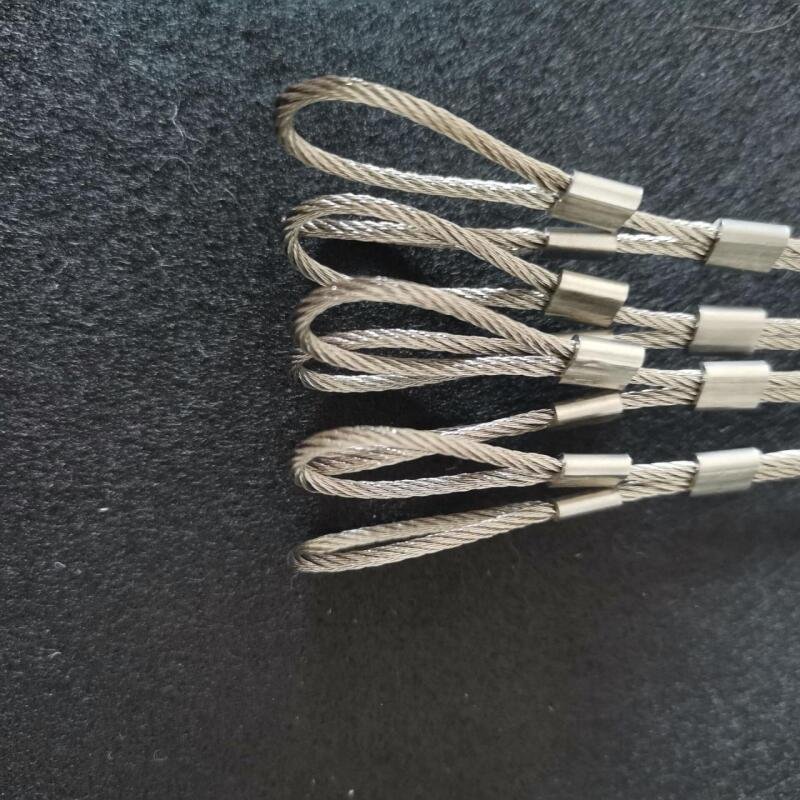

- Unique construction: Incorporates stainless steel cables, ferrules for robustness, aesthetics.

Stainless steel cable netting, also known as X-TEND mesh or Webnet, uses strong DIN 1.4401/AISI 316 stainless steel cables. Workers swage these cables with tinned copper (type CX) or stainless steel (types CXE and CXS) clamps in a special process. This creates a flexible mesh structure that works well for both two-dimensional and three-dimensional uses. X-TEND keeps its shape forever and lasts a long time.

Workers make X-TEND from high-quality stainless steel cables (material: AISI316). They connect these cables using stainless steel ferrules through a special method. This forms a flexible structure for both flat and three-dimensional applications. X-TEND maintains its shape forever and requires little maintenance over its long lifetime.

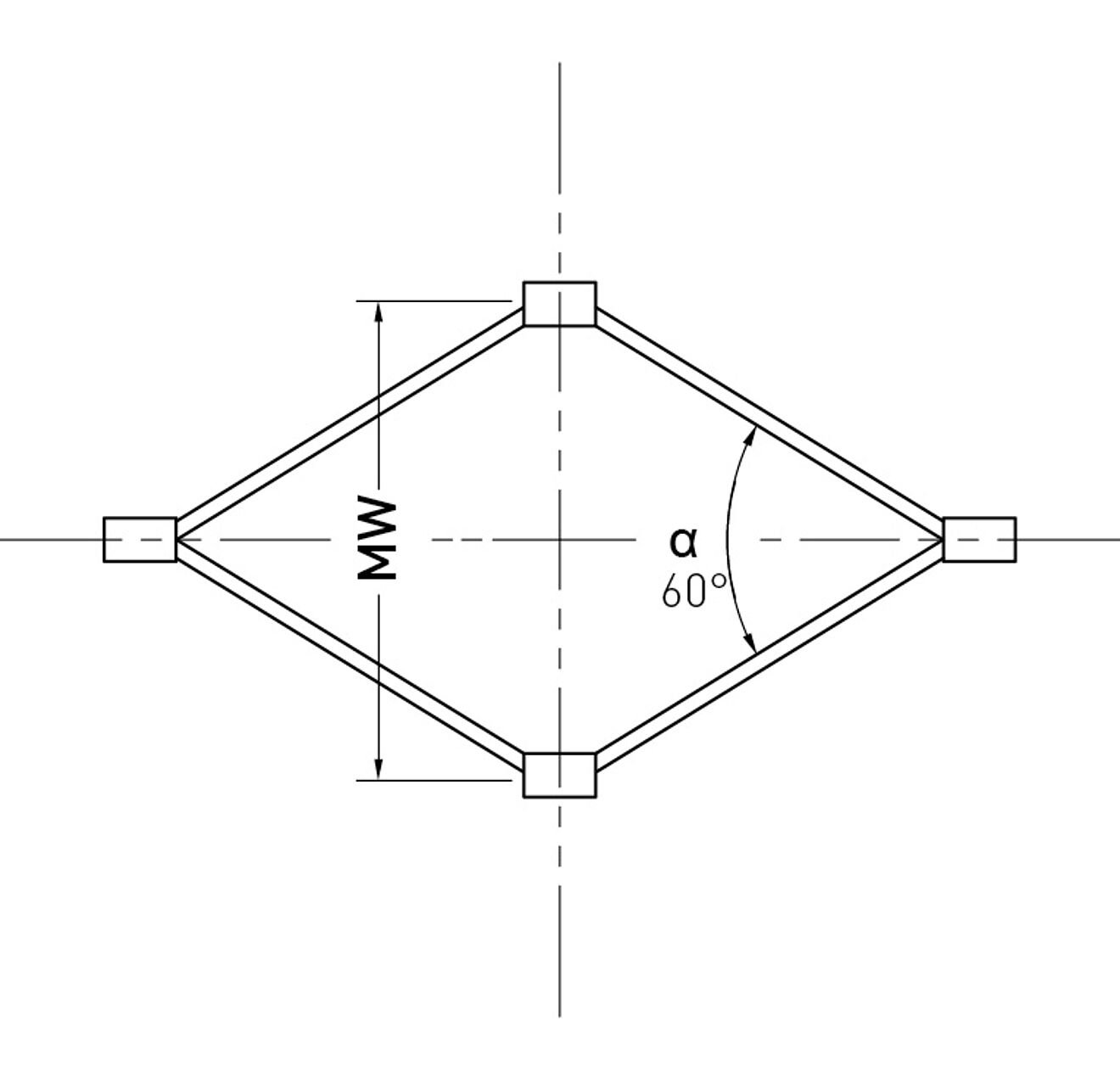

Mesh geometry

- The X-Tend Mesh width (MW) refers to the distance from the centre of one ferrule to the centre of the next ferrule. The optimal mesh geometry with an opening angle of 60° is given when the mesh width and the distance between the ferrules’ centres along the mesh’s cables

- are equal. This results in the ideal tension of the mesh and is the mathematical basis for the quantity take-off.

- MW Mesh width (distance from center to center of ferrule) α Standard mesh opening 60 °

Conclusion

In summary, X-TEND® mesh is a versatile solution for indoor and outdoor use. Its flexibility, safety, durability, and aesthetics make it popular among architects and builders. It’s adaptable to various shapes and structures, ensuring reliability in projects like balustrades, fall protection, green walls, and animal enclosures. Whether enhancing building facades or ensuring safety in public areas, X-TEND® mesh excels in performance and functionality.