Introducing our ferrule cable mesh: A versatile, resilient, and customizable Stainless steel wire rope mesh solution that caters to a wide range of applications. This high-quality mesh is made using seamless ferrules that combine cables together to create a flexible metal fabric with rhombus holes, allowing it to easily adapt to your most challenging 3-D tensile projects.

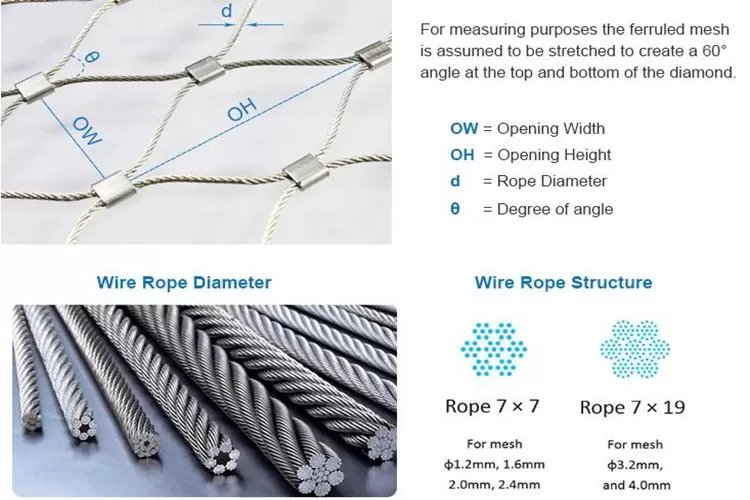

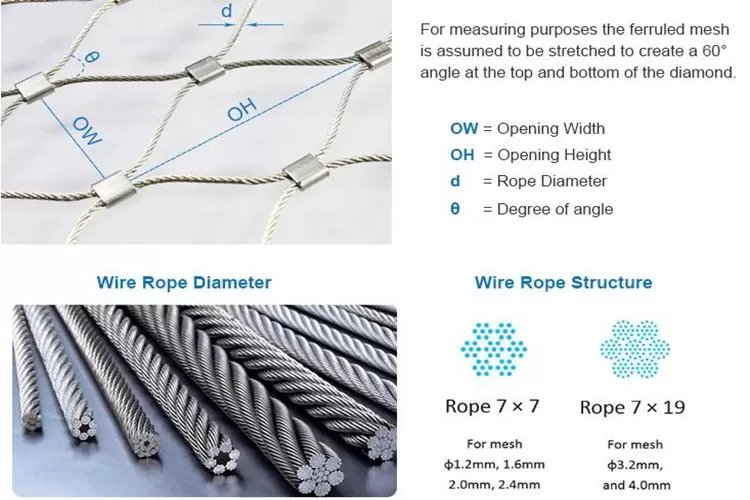

Specifications:

- Ferrule Cable Mesh material: tinned copper, nickel plated copper, stainless steel, or aluminum.

- material: high tensile stainless steel AISI 304, 304L, 316, 316L.

- Cable construction: 7 × 7 (1.5 mm, 2 mm, or 2.5 mm), 7 × 19 (3 mm, 4 mm) Diamond size: 20 mm to 200 mm.

- diameter: 1 mm to 4 mm.

Strength of Ferrule Cable Mesh

| Diameter |

1 mm |

1.2 mm |

1.5 mm |

2 mm |

2.5 mm |

3 mm |

4 mm |

5 mm |

| Tensile Strength (Ft) |

90 lbs |

112 lbs |

180 lbs |

315 lbs |

450 lbs |

539 lbs |

764 lbs |

1146 lbs |

| Breaking Load (Fb) |

315 lbs |

404 lbs |

517 lbs |

764 lbs |

877 lbs |

989 lbs |

1281 lbs |

1573 lbs |

Advantages of Ferrule Cable Mesh

- High transparency: Dense diamond holes allow plenty of light and air through, providing excellent visibility.

- High strength: Quality materials and seamless ferrules ensure high load capacity and dependability.

- Flexible & impact resistant: The flexible structure is perfect for use as balustrades on bridges, paths, and stairs.

- Non-flammable: Ferrule Cable Mesh is environmentally friendly and non-flammable, ideal for fire escapes.

- Anti-climb: Small rhombus patterns effectively deter climbing, securing museums, schools, and play areas.

- Weather-resistant: Made from quality stainless steel, it resists harsh weather and UV rays.

- Easy installation & maintenance-free: Attach quickly to steel frames using simple hardware; no periodic adjustments needed.

- Customizable: Available in various patterns, sizes, and cable diameters to meet specific project needs.

- Long lifespan: Lasts over 30 years with high recyclability, offering a sustainable and cost-effective solution.

Comparing ferrule cable mesh to knotted cable mesh reveals several disadvantages:

Flexibility: Ferrule cable mesh generally offers less flexibility. Ferrules lock cables at crossing points, restricting movement. This may not suit applications requiring mesh to adapt to irregular shapes or absorb impacts softly.

Ease of Repair: Repairing ferrule mesh can be more complex. Damaged ferrules or cables may need specialized tools or specific replacement parts. Conversely, knotted cable mesh allows easier on-site repairs as knots can be adjusted or retied without special components.

Aesthetic Versatility: ferrule cable mesh typically looks more uniform and industrial because of metal ferrules at each intersection. This might not fit projects needing a more natural or subtle appearance. Knotted cable mesh provides a more organic look that blends better with natural settings.

Cost and Installation Complexity: Ferrule mesh is often more expensive due to higher material costs and the precision needed in manufacturing and installation. Accurate placement of ferrules can increase labor costs and installation time.

Structural Rigidity: The rigidity of ferrule cable mesh can be an advantage for durability and maintaining shape but a disadvantage for adaptability. Knotted cable mesh provides better shock absorption and flexibility, essential in dynamic environments like animal enclosures or play areas.

Conclusion

Choose our Ferrule Cable Mesh for a durable, flexible, and low-maintenance solution that delivers unmatched performance and adaptability for your next project.