» Blog » Zoo Mesh: The Key to Safe and Engaging Animal Enclosures

Zoo Mesh: The Key to Safe and Engaging Animal Enclosures

April 14, 2024

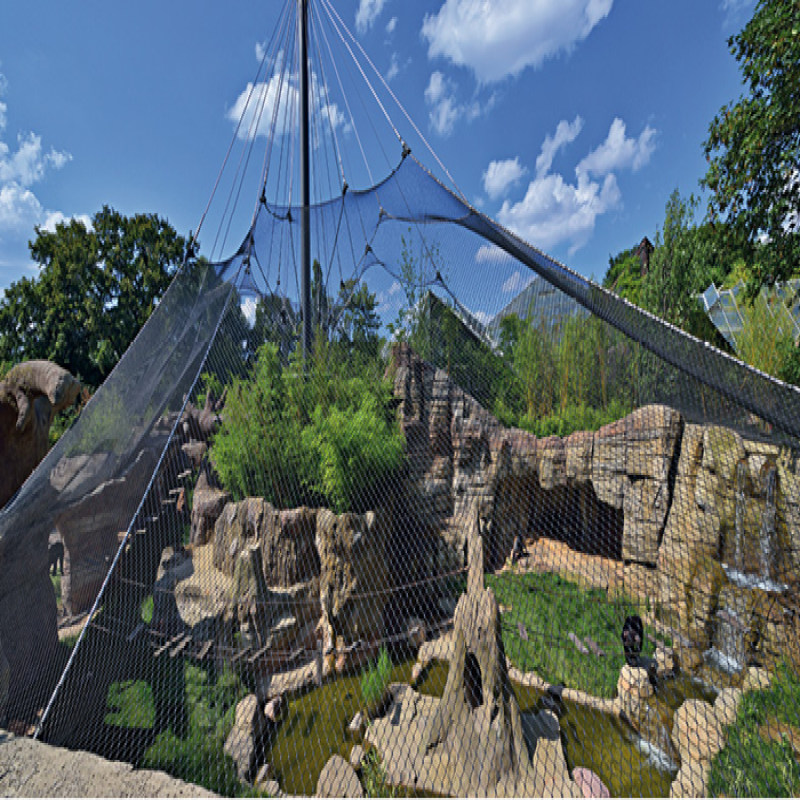

Zoo mesh is a unique type of fencing used in zoos, sanctuaries, and wildlife conservation areas. It keeps animals safe and healthy and allows visitors to see them clearly. Crafted from durable stainless steel, zoo mesh can flex and adapt to different spaces. It improves upon older fencing styles by increasing airflow and maintaining unobstructed views. Depending on the specific needs of each animal type, zoos can choose either woven or welded wire mesh.

Key Properties and Benefits zoo mesh

Zoo mesh offers outstanding strength, corrosion resistance, and minimal maintenance. These properties allow it to endure harsh outdoor conditions and aggressive animal behaviors. Its durability and security reduce the need for frequent replacements and repairs.

Importance in Modern Zoos

Zoo mesh is essential for modern zoos and animal preserves, ensuring animal safety without harming their habitats. It creates barriers that mimic natural environments, supporting animal health and well-being.

Enhancing Animal Safety

Zoo mesh protects animals from external threats and prevents escapes. This keeps both animals and visitors safe. Zoos use this mesh to securely contain various animal species, including potentially dangerous ones.

Improving Visitor Experiences zoo mesh

Zoo mesh is nearly invisible from a distance, enhancing visitor experiences by providing clear views. This transparency allows visitors to observe natural animal behaviors. It also enhances the zoo’s aesthetic, making enclosures both beautiful and immersive.

Types of Zoo Mesh

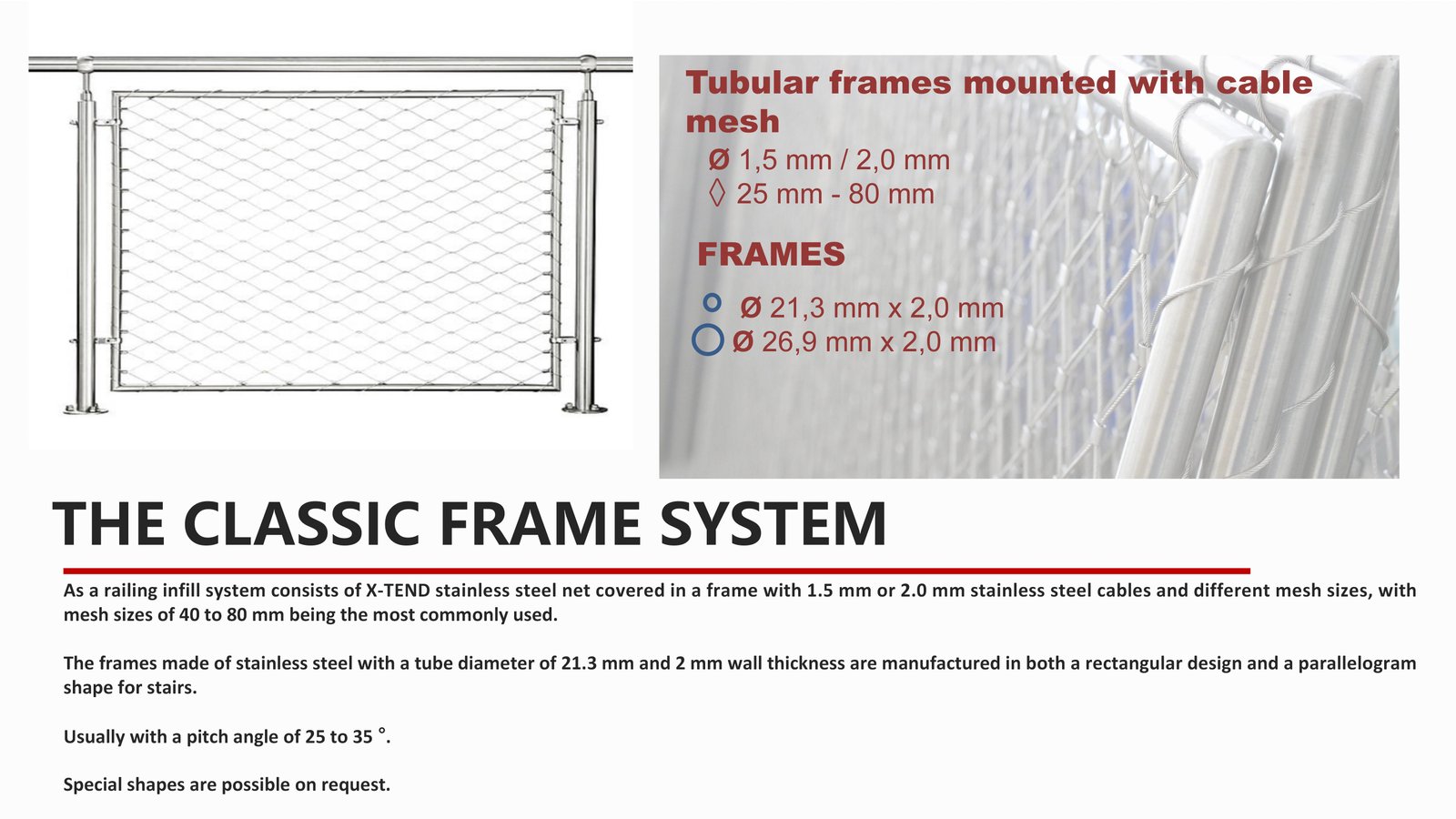

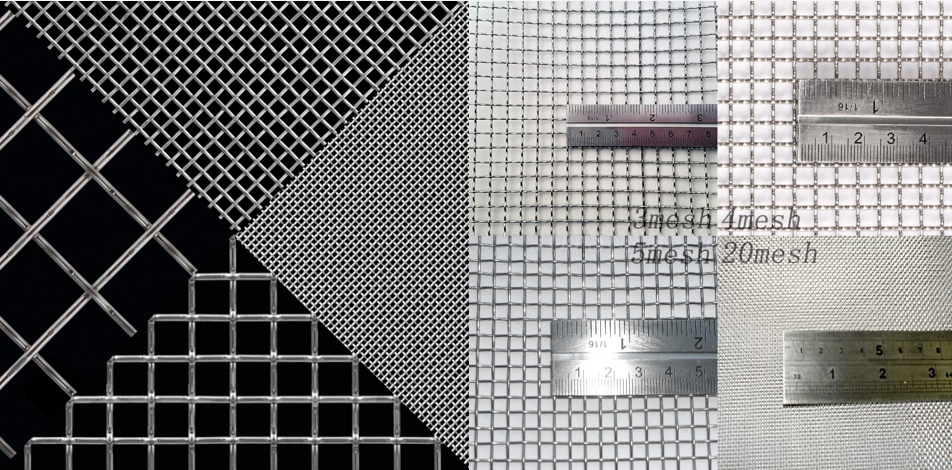

Zoo mesh comes in several types, each designed for different needs in zoos and wildlife sanctuaries. Stainless steel rope mesh is popular for its strength and clear view, making it perfect for aviaries and enclosures for predators. You can choose from ferrule type, which uses ferrules to connect cables smoothly, or knotted type, which is stronger for tougher environments. Welded wire mesh is great for smaller mammals and reptiles because of its stiff structure.

Chain link mesh is a less expensive option that works well for larger enclosures. It’s durable and flexible. Expanded metal mesh is best for high-security areas because it’s very solid and prevents any escapes or break-ins. For lighter needs, like small bird aviaries, crimped wire mesh is ideal because it resists corrosion and allows good visibility. Each mesh type meets specific safety needs, visibility levels, and suits the natural behavior of the animals it holds.

Specifications ferrule rope mesh

| Item No.s | Cable Diameter | Mesh Opening Size(W×H) | ||

| inch | mm | inch | mm | |

| BZ-32120F | 1/8 | 3.2 | 4.75 x 8.23 | 120 x 207.8 |

| BZ-32102F | 1/8 | 3.2 | 4 x 6.9 | 102 x 176.7 |

| BZ-3290F | 1/8 | 3.2 | 3.55 x 6.15 | 90 x 156 |

| BZ-3276F | 1/8 | 3.2 | 3 x5.2 | 76 x 131.6 |

| BZ-3251F | 1/8 | 3.2 | 2 x3.46 | 51 x88.3 |

| BZ-24102F | 3/32 | 2.4 | 4×6.9 | 102×176.7 |

| BZ-2490F | 3/32 | 2.4 | 3.55×6.15 | 90x 156 |

| BZ-2476F | 3/32 | 2.4 | 3 x 5.2 | 76x 131.6 |

| BZ-2460F | 3/32 | 2.4 | 2.4x 4.16 | 60x 104 |

| BZ-2451F | 3/32 | 2.4 | 2×3.46 | 51 x 88.3 |

| BZ-2076F | 5/64 | 2.0 | 3 x 5.2 | 76 x 131.6 |

| BZ-2060F | 5/64 | 2.0 | 2.4x 4.16 | 60 x 104 |

| BZ-2051F | 5/64 | 2.0 | 2 x 3.46 | 51 x 88.3 |

| BZ-2038F | 5/64 | 2.0 | 1-1/2 x 2.6 | 38 x 65.8 |

| BZ-1676F | 1/16 | 1.6 | 1.2 x2.08 | 76 x 131.6 |

| BZ-1651F | 1/16 | 1.6 | 2x 3.46 | 51 x 88.3 |

| BZ-1638F | 1/16 | 1.6 | 1-1/2 x 2.6 | 38 x 65.8 |

| BZ-1630F | 1/16 | 1.6 | 1.2×2.08 | 30 x 52 |

| BZ-1625F | 1/16 | 1.6 | 1 x 1.73 | 25.4 x 44 |

| BZ-1238F | 3/64 | 1.2 | 1-1/2×2.6 | 38 x 65.8 |

| BZ-1230F | 3/64 | 1.2 | 1.2 x 2.08 | 30 x 52 |

| BZ-1225F | 3/64 | 1.2 | 1 x 1.73 | 25.4 x 44 |

| BZ-1220F | 3/64 | 1.2 | 4/5 x 1.39 | 20 x 34.6 |

Specifications Knotted Rope zoo mesh:

Unlike ferrule rope mesh, knotted rope mesh uses knots to secure the intersections, providing a robust and secure form of enclosure. This type is highly durable and often used for larger, heavier animals due to its superior strength.

| Item No.s | Cable Diameter | Cable Diameter (mm) | Mesh Opening Size | Mesh Opening Size (mm) |

|---|---|---|---|---|

| BMP-3212W | 1/8″ | 3.2 | 4.75 x 4.75 | 120 x 120 |

| BMP-3210W | 1/8″ | 3.2 | 4 x 4 | 102 x 102 |

| BMP-3290W | 1/8″ | 3.2 | 3.55 x 3.55 | 90 x 90 |

| BMP-3276W | 1/8″ | 3.2 | 3 x 3 | 76 x 76 |

| BMP-3250W | 1/8″ | 3.2 | 2 x 2 | 51 x 51 |

| BMP-2410W | 3/32″ | 2.4 | 4 x 4 | 102 x 102 |

| BMP-2490W | 3/32″ | 2.4 | 3.55 x 3.55 | 90 x 90 |

| BMP-2476W | 3/32″ | 2.4 | 3 x 3 | 76 x 76 |

| BMP-2460W | 3/32″ | 2.4 | 2.4 x 2.4 | 60 x 60 |

| BMP-2450W | 3/32″ | 2.4 | 2 x 2 | 51 x 51 |

| BMP-2076W | 5/64″ | 2.0 | 3 x 3 | 76 x 76 |

| BMP-2060W | 5/64″ | 2.0 | 2.4 x 2.4 | 60 x 60 |

| BMP-2050W | 5/64″ | 2.0 | 2 x 2 | 51 x 51 |

| BMP-2038W | 5/64″ | 2.0 | 1-1/2 x 1-1/2 | 38 x 38 |

| BMP-1676W | 1/16″ | 1.6 | 3 x 3 | 76 x 76 |

| BMP-1650W | 1/16″ | 1.6 | 2 x 2 | 51 x 51 |

| BMP-1638W | 1/16″ | 1.6 | 1-1/2 x 1-1/2 | 38 x 38 |

| BMP-1630W | 1/16″ | 1.6 | 1.2 x 1.2 | 30 x 30 |

| BMP-1625W | 1/16″ | 1.6 | 1 x 1 | 25.4 x 25.4 |

| BMP-1238W | 3/64″ | 1.2 | 1-1/2 x 1-1/2 | 38 x 38 |

| BMP-1230W | 3/64″ | 1.2 | 1.2 x 1.2 | 30 x 30 |

| BMP-1225W | 3/64″ | 1.2 | 1 x 1 | 25.4 x 25.4 |

| BMP-1220W | 3/64″ | 1.2 | 4/5 x 4/5 | 20 x 20 |

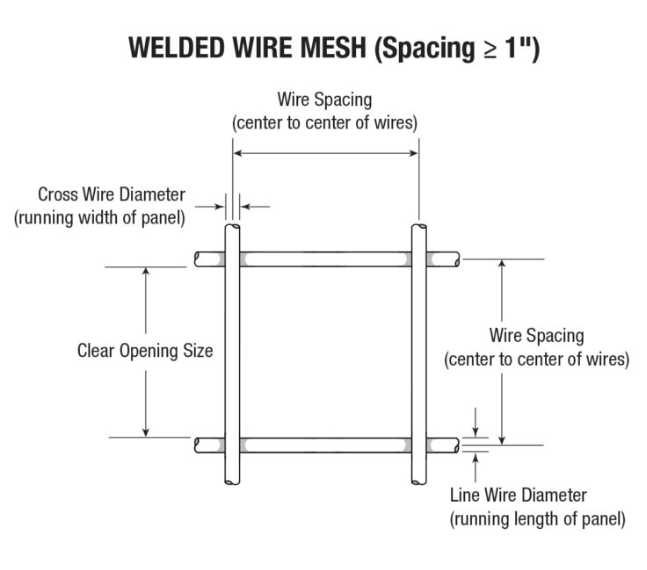

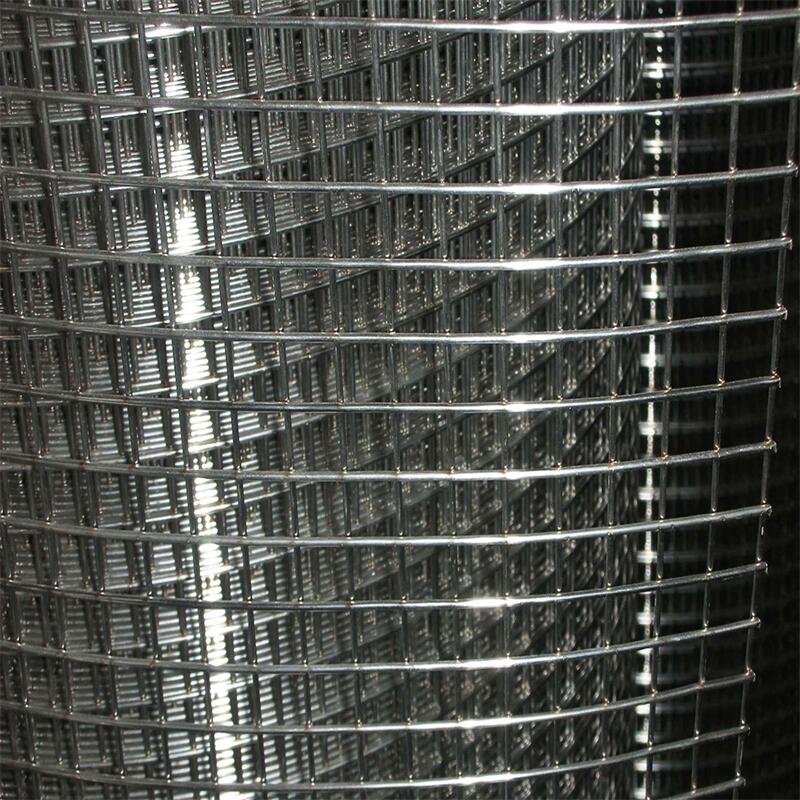

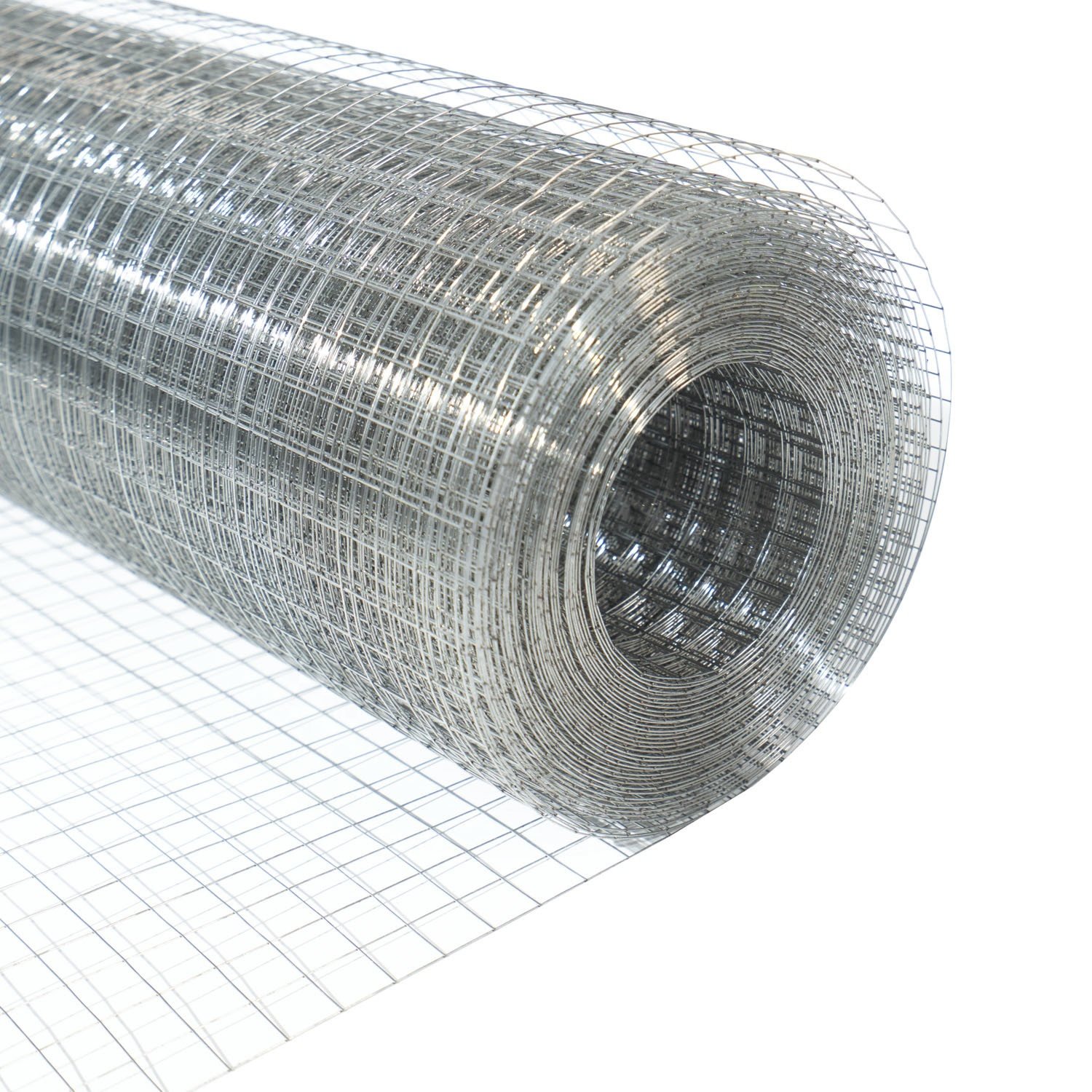

2. Welded Wire Mesh

Welded wire mesh is made by welding steel wires at every intersection, creating a uniform and sturdy grid. It is commonly used for mammals and birds due to its high security and ability to withstand significant force.

Galvanized Wire Mesh

| Opening | Wire Diameter (BWG) | In Inches | In Metric Units (mm) |

|---|---|---|---|

| 1/4″ x 1/4″ | 22, 23, 24 | 6.4mm x 6.4mm | 6.4 x 6.4 |

| 3/8″ x 3/8″ | 19, 20, 21, 22 | 10.6mm x 10.6mm | 10.6 x 10.6 |

| 1/2″ x 1/2″ | 16, 17, 18, 19, 20, 21, 22, 23 | 12.7mm x 12.7mm | 12.7 x 12.7 |

| 5/8″ x 5/8″ | 18, 19, 20, 21 | 16mm x 16mm | 16 x 16 |

| 3/4″ x 3/4″ | 16, 17, 18, 19, 20, 21 | 19.1mm x 19.1mm | 19.1 x 19.1 |

| 1″ x 1/2″ | 16, 17, 18, 19, 20, 21 | 25.4mm x 12.7mm | 25.4 x 12.7 |

| 1-1/2″ x 1-1/2″ | 14, 15, 16, 17, 18, 19 | 38mm x 38mm | 38 x 38 |

| 1″ x 2″ | 14, 15, 16 | 25.4mm x 50.8mm | 25.4 x 50.8 |

| 2″ x 2″ | 12, 13, 14, 15, 16 | 50.8mm x 50.8mm | 50.8 x 50.8 |

Galvanized Weld Wire Mesh for Zoo Mesh

| Opening | Wire Diameter (mm) | In Inches | In Metric Units (mm) |

|---|---|---|---|

| 2″ x 3″ | 2.0, 2.5, 1.65 | 50mm x 75mm | 50 x 75 |

| 3″ x 3″ | 2.67, 2.41, 2.11, 1.83, 1.65 | 75mm x 75mm | 75 x 75 |

| 2″ x 4″ | 2.11, 2.5 | 50mm x 100mm | 50 x 100 |

| 4″ x 4″ | 2.0, 2.5 | 100mm x 100mm | 100 x 100 |

PVC Coated Welded Mesh

| Opening | Wire Diameter (BWG) | In Inches | In Metric Units (mm) |

|---|---|---|---|

| 1/2″ x 1/2″ | 16, 17, 18, 19, 20, 21 | 12.7mm x 12.7mm | 12.7 x 12.7 |

| 3/4″ x 3/4″ | 16, 17, 18, 19, 20, 21 | 19mm x 19mm | 19 x 19 |

| 1″ x 1″ | 15, 16, 17, 18, 19, 20 | 25.4mm x 25.4mm | 25.4 x 25.4 |

Stainless Steel Welded Wire Mesh

General Purpose Stainless Steel Welded Mesh (30m Rolls)

Stainless steel welded wire mesh is a highly durable, strong, and versatile material made by welding steel wires together at their intersections. It offers excellent resistance to rust and corrosion due to its stainless steel composition, making it ideal for a wide range of applications. The mesh is available in various gauges and sizes, allowing for its use in industrial, architectural, and horticultural projects as well as in zoos for animal enclosures. Its aesthetic appeal is appreciated in design applications, while its functionality is valued in structural uses. The welded points ensure stability and rigidity, making it a reliable choice for fencing, support structures, and safety barriers.

| Mesh mm | Diam mm | Width mm | Grade 304 | Grade 316 |

|---|---|---|---|---|

| 6.35 x 6.35 | 0.63 | 190.5 | ✓ | |

| 6.35 x 6.35 | 0.63 | 915 | ✓ | ✓ |

| 6.35 x 6.35 | 0.63 | 1220 | ✓ | |

| 6.35 x 6.35 | 0.80 | 1220 | ✓ | ✓ |

| 9.50 x 9.50 | 0.80 | 1220 | ✓ | |

| 9.50 x 9.50 | 1.00 | 1220 | ✓ | ✓ |

| 9.50 x 9.50 | 1.00 | 1525 | ✓ | ✓ |

| 11.0 x 11.0 | 0.80 | 1220 | ✓ | ✓ |

| 12.7 x 12.7 | 1.00 | 1220 | ✓ | ✓ |

| 50.8 x 50.8 | 2.00 | 1220 | ✓ |

General Purpose Stainless Steel Welded Panels (1200mm x 2400mm)

| Mesh mm | Diam mm | Width mm | Grade 304 | Grade 316 |

|---|---|---|---|---|

| 25 x 25 | 2.5 | 1200 | ✓ | ✓ |

| 25 x 25 | 3.00 | 1200 | ✓ | ✓ |

| 25 x 50 | 3.00 | 1200 | ✓ | |

| 40 x 40 | 3.00 | 1200 | ✓ | ✓ |

| 40 x 40 | 4.00 | 1200 | ✓ | ✓ |

| 50 x 50 | 3.00 | 1200 | ✓ | ✓ |

| 200 x 200 | 6.00 | 1200 | ✓ |

Stainless Steel Roof Safety Mesh (1800mm x 30m Rolls)

| Mesh mm | Diam mm | Grade | Finish |

|---|---|---|---|

| 150 x 300 | 2 | 316 | Uncoated |

| 150 x 300 | 2 | 316 | Black PVC |

Stainless Steel Welded Mesh (30m Rolls)

| Mesh mm | Diam mm | Width mm | Grade |

|---|---|---|---|

| 6.35 x 6.35 | 0.80 | 1220 | 304 |

| 9.50 x 9.50 | 1.00 | 1220 | 304 |

| 12.7 x 12.7 | 1.00 | 1220 | 304 |

3. Crimped Wire Mesh

Crimped wire mesh involves bending stainless steel wires in zigzag patterns before weaving them. This pre-crimping process adds extra structural strength, making it suitable for medium-sized animal enclosures and areas requiring additional security.

| Wire Diameter (mm) | Aperture (mm) | Mesh | Length (M) | Weight (Kg) |

|---|---|---|---|---|

| 4.00 | 40 | 0.58 | 30 | 142 |

| 4.00 | 30 | 0.75 | 30 | 182 |

| 4.00 | 25 | 0.87 | 30 | 213 |

| 3.2 | 25 | 0.87 | 30 | 141 |

| 3.2 | 20 | 1.1 | 30 | 169 |

| 2.6 | 20 | 1.12 | 30 | 116 |

| 2.6 | 18 | 1.23 | 30 | 127 |

| 2.6 | 15 | 1.44 | 30 | 173 |

| 2.0 | 15 | 1.49 | 30 | 92 |

| 2.0 | 12 | 1.8 | 30 | 110 |

| 2.0 | 10 | 2.12 | 30 | 127 |

| 2.0 | 8 | 2.54 | 30 | 155 |

| 1.8 | 7 | 3.0 | 30 | 149 |

| 1.8 | 6 | 3.25 | 30 | 161 |

| 1.6 | 7 | 3.0 | 30 | 117 |

| 1.6 | 6 | 3.35 | 30 | 131 |

| 1.6 | 5 | 3.85 | 30 | 150 |

| 1.6 | 4 | 4.5 | 30 | 176 |

| 1.6 | 3 | 5.5 | 30 | 215 |

| 1.4 | 6 | 3.5 | 30 | 105 |

| 1.4 | 5 | 4.0 | 30 | 120 |

| 1.4 | 4 | 4.7 | 30 | 140 |

| 1.2 | 8 | 2.7 | 30 | 59 |

| 1.2 | 7 | 3.1 | 30 | 68 |

4. Hexagonal Wire Mesh

Also known as chicken wire, hexagonal wire mesh is formed by twisting thin wires into hexagonal openings. It’s often used for small bird enclosures or small mammal habitats, providing adequate protection and confinement with minimal material use.

specifications for hexagonal wire mesh:

| Type | Mesh Size (inch) | Mesh Size (mm) | Wire Gauge/Diameter (BWG/mm) |

|---|---|---|---|

| Galvanized (Normal Twist) | 3/8″ | 10 | 32, 31, 30, 29, 28, 27, 26, 25, 24, 23, 22, 21 |

| Galvanized (Normal Twist) | 1/2″ | 13 | 27, 26, 25, 24, 23, 22, 21, 20 |

| Galvanized (Normal Twist) | 5/8″ | 16 | 32, 31, 30, 29, 28, 27, 26, 25, 24, 23, 22, 21 |

| Galvanized (Normal Twist) | 3/4″ | 20 | 25, 24, 23, 22, 21, 20, 19 |

| Galvanized (Normal Twist) | 1″ | 25 | 27, 26, 25, 24, 23, 22, 21, 20, 19, 18 |

| Galvanized (Normal Twist) | 1-1/4″ | 32 | 23, 22, 21, 20, 19, 18 |

| Galvanized (Normal Twist) | 1-1/2″ | 40 | 23, 22, 21, 20, 19, 18, 17 |

| Galvanized (Normal Twist) | 2″ | 50 | 23, 22, 21, 20, 19, 18, 17, 16, 15, 14 |

| Galvanized (Normal Twist) | 2-1/2″ | 65 | 21, 20, 19, 18 |

| Galvanized (Normal Twist) | 3″ | 75 | 21, 20, 19, 18, 17, 16, 15, 14 |

| Galvanized (Normal Twist) | 4″ | 100 | 19, 18, 17, 16, 15, 14 |

| Galvanized (Reverse Twist) | 1″ | 25 | 25, 24, 23, 22, 21, 20, 19, 18 |

| Galvanized (Reverse Twist) | 1-1/4″ | 32 | 23, 22, 21, 20, 19, 18 |

| Galvanized(Reverse Twist) | 1-1/2″ | 40 | 23, 22, 21, 20, 19, 18, 17 |

| Galvanized (Reverse Twist) | 2″ | 50 | 23, 22, 21, 20, 19, 18, 17, 16 |

| Galvanized (Reverse Twist) | 3″ | 75 | 20, 19, 18, 17, 16 |

Please note that the values provided in the table are a general representation of the specifications. The actual specifications may vary depending on the manufacturer and the specific needs of the application. Always consult with the manufacturer to determine the best specifications for your particular project.

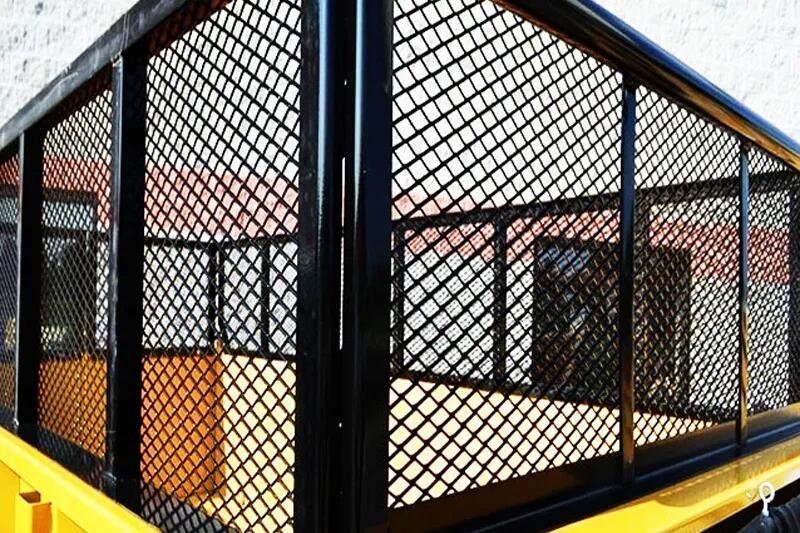

5. Expanded Metal Zoo Enclosures

Expanded metal mesh is produced by slitting and stretching metal sheets to create an open diamond pattern. This mesh is durable and provides good visibility and security, making it suitable for a variety of animal enclosures, including those for birds and reptiles.

Expanded Metal Zoo Enclosure Specifications Table

| Specification | Options |

|---|---|

| Material | Aluminum, mild steel, stainless sheet, galvanized steel, etc. (customized) |

| Hole Patterns | Diamond hole, hexagon hole, sector hole, etc. |

| Hole Size (mm) | 8×16, 10×20, 20×40, 30×60, 40×60, 40×80, 60×100, 100×150, etc. (customized) |

| Strand Size (mm) | 0.2mm — 10mm |

| Thickness (mm) | 0.1mm — 3mm |

| Sheet Size | Customized by buyer |

| Surface Treatment | Powder coating, PVDF Coating, galvanization, anodizing, etc. |

| Applications | Facade cladding, curtain wall, architectural cladding, security fencing, etc. |

| Packing Methods | Wooden case with plaster film, wooden/steel pallet, or other special methods |

| Quality Control | ISO Certificate, SGS Certificate |

| After-sale Service | Product test report, online follow up |

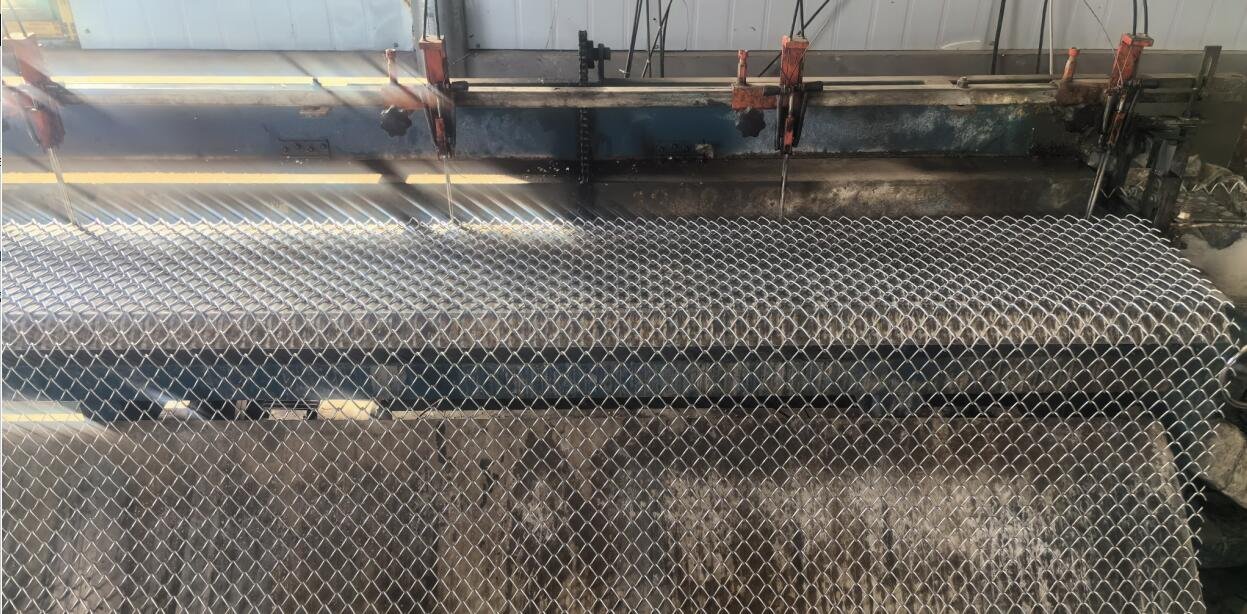

6. Chain Link Fence

Chain link fence is another popular type of zoo mesh. Made from galvanized or coated steel wire woven into a diamond pattern, chain link fences are cost-effective and easy to install. They provide a high level of security and are often used for larger animal enclosures and perimeter barriers around the zoo.

Specifications chain link fence for zoo

| Opening Size (mm) | Wire Diameter (mm) | Surface Treatment | Mesh Width (m) | Mesh Length (m) |

|---|---|---|---|---|

| 200×200 | 4 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 150×150 | 3 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 100×100 | 3.5 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 80×80 | 3 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 60×60 | 2.5 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 50×50 | 2.5 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 40×40 | 3 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 30×30 | 2.5 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 20×20 | 1 | Hot-dip galvanized | 0.5-5.0 | 1-50 |

| 80×80 | 3.0/4.0 (PVC coated) | PVC Coating | 0.5-5.0 | 1-50 |

| 60×60 | 2.5/3.5 (PVC coated) | PVC Coating | 0.5-5.0 | 1-50 |

| 55×55 | 2.0/3.0 (PVC coated) | PVC Coating | 0.5-5.0 | 1-50 |

| 50×50 | 2.0/3.0 (PVC coated) | PVC Coating | 0.5-5.0 | 1-50 |

| 45×45 | 3.0/4.0 (PVC coated) | PVC Coating | 0.5-5.0 | 1-50 |

| 40×40 | 2.0/3.0 (PVC coated) | PVC Coating | 0.5-5.0 | 1-50 |

Chain Link Fence for Small Birds Avairy

| Wire Diameter (mm) | Mesh Size (mm) | Roll Length (m) | Standard Netting Heights (mm) | Standard Post Heights (mm) |

|---|---|---|---|---|

| 1 | 5×5 | 10 | 500 | 1000 |

| 1 | 5×5 | 10 | 1000 | 1500 |

| 1.2 | 10×10 | 10 | 1250 | 2000 |

| 1.2 | 20×20 | 10 | 1500 | 2000 |

| 1.4 | 20×20 | 10 | 2000 | 2500 |

| 1.8 | 30×30 | 10 | 2500 | 3000 |

| 2.5 | 40×40 | 10 | 3000 | 3500 |

| 2.8 | 50×50 | 10 | 4000 | 4500 |

| 3 | 50×50 | 10 | 5000 | 5500 |

Applications of Zoo Mesh

Zoo mesh has transformed the way zoological environments are created and maintained, blending the practical aspects of animal safety with the aesthetic demands of modern design. This versatile material has found applications in various areas of zoo construction and management, notably in the creation of animal enclosures and safety barriers.

Animal Enclosures zoo mesh

Birds and Aviaries

For our feathered friends, the zoo mesh provides not only a boundary but also a space to thrive. The specific mesh type selected for aviaries is crucial to accommodate the diverse species housed within. Smaller mesh apertures are typically used for tiny, nimble birds like finches and canaries, preventing them from slipping through gaps or becoming injured. Conversely, larger birds such as eagles or vultures require a more robust mesh that can withstand the force of their beaks and talons, often made from heavier gauge wire.

Mammals

When it comes to mammals, the size and strength of the animals are significant considerations. Zoo mesh for primate enclosures, for instance, needs to be exceptionally strong to withstand their climbing and swinging habits. Large cats, like lions and tigers, demand a mesh that can handle the raw power and agility inherent to these magnificent creatures. The mesh must provide security without compromising the view – a factor that enhances educational visibility for zoo visitors.

Visitor Safety

Zoo mesh enhances visitor safety by serving a dual purpose. It keeps a safe distance between visitors and the animals, preventing any potential harm. Zoo designers carefully plan the placement and height of mesh barriers to stop people from climbing or reaching into enclosures while keeping views clear. These barriers act as silent guardians—effective yet unobtrusive.

Animal Containment

The safety and ethical reputation of a zoo greatly depend on its ability to prevent animal escapes. Zoo staff tailor mesh barriers to fit the behavioral patterns and physical abilities of each species. For instance, they design mesh for aquatic enclosures to resist corrosion from water. Similarly, they make mesh for monkey islands flexible yet strong enough to allow natural movement without risking escape.

Installation Techniques for Zoo Mesh

The proper installation of zoo mesh is as critical as its design and material selection. From planning to the final touches, each step requires meticulous attention to detail to ensure the mesh not only serves its functional purpose but also enhances the overall aesthetic of the zoo.

Planning and Design

Measuring and Custom Fitting

Before any zoo mesh can be installed, precise measurements of the enclosures must be taken. This is a critical step, as custom fitting is often required to meet the unique dimensions and contours of each space. To measure an enclosure for mesh fitting, a comprehensive understanding of the area’s perimeter and any potential obstructions is necessary. These measurements will dictate the size and shape of the mesh panels needed.

Aesthetic Integration

Integrating the zoo mesh with the overarching theme and design of the zoo requires a keen eye for detail. The mesh should complement the naturalistic habitats created for the animals, and it should be as invisible as possible to give visitors the illusion of an uninterrupted view. When planning, consider how the mesh will blend with the vegetation, rocks, and other design elements to create a cohesive and immersive environment.

Physical Installation

Tools and Equipment Needed

A successful installation hinges on having the right tools and equipment. Necessary items typically include:

- Measuring tape for accurate dimensions

- Wire cutters for trimming the mesh to size

- Pliers for manipulating the wire

- Tensioning tools to ensure the mesh is taut and secure

- Fasteners and anchors appropriate for the specific installation surfaces

- Protective gear to ensure the safety of the installation team

Step-by-Step Installation Process

The installation process for zoo mesh generally follows these steps:

- Preparation: Clear the area of any debris or obstructions. If needed, prepare the ground or surface where the mesh will be anchored.

- Measuring: Using the measurements taken during the planning phase, cut the mesh to the required size, leaving a little extra for adjustments.

- Positioning: Place the cut mesh against the enclosure’s structure, ensuring it fits correctly and evenly. Adjust as necessary before securing it.

- Securing: Begin at one corner, using tensioning tools to pull the mesh taut. Secure the mesh to the structure using the appropriate fasteners, working your way along the mesh to avoid any sagging or gaps.

- Final Inspection: Once the mesh is installed, inspect the entire surface to ensure there are no loose areas or potential escape points. Test the stability of the mesh by applying gentle pressure.

- Finishing Touches: Trim any excess material and make sure all fasteners are covered or filed down to prevent injury to the animals or visitors.

Following this methodical approach, zoo mesh can be installed efficiently and safely, maintaining the integrity of the animal enclosures while supporting the aesthetic value of the zoo’s environment. The end goal is always to create enclosures that are secure, durable, and as invisible as possible to provide an immersive experience for visitors and a comfortable habitat for the animals.

Maintenance and Care of Zoo Mesh

Routine Inspections

Consistent inspections are a critical aspect of zoo mesh maintenance. Frequent checks ensure the integrity and safety of animal enclosures. These inspections should be thorough and focused on key areas such as the mesh’s tension, the condition of fasteners, signs of wear or corrosion, and any potential damage caused by animals or environmental factors. A checklist for regular maintenance should include:

- Checking for broken wires or loose connections.

- Inspecting the mesh for signs of rust or corrosion, especially in welded areas.

- Ensuring that the mesh has not been stretched or deformed.

- Verifying that all gates and openings function correctly and securely.

Repair and Replacement

Identifying When Repairs Are Needed

Damage to the zoo mesh can compromise the safety of both the animals and the visitors. It’s crucial to identify when repairs are necessary—typically when there are visible signs of damage such as broken wires or when the mesh has been significantly deformed.

Techniques for Repairing Minor Damages

For minor damages, repair techniques might include rewelding broken wires or replacing small sections of the mesh. It’s important to address these repairs quickly to prevent larger issues.

Full Replacement Considerations

Sometimes, damages or the wear and tear of time necessitate a complete replacement of the mesh. Factors influencing this decision include the extent of corrosion, irreversible deformation, or when a particular area has undergone repeated repairs. The complete replacement should be carried out by professionals, following the original installation protocols to ensure the continued safety and structural integrity of the enclosures.

Case Studies and Examples of Zoo Mesh

Successful Implementations

Several zoos across the globe have successfully implemented zoo mesh in their designs. For instance, the aviary mesh at the Singapore Bird Park provides an unobstructed view while ensuring the safety of its diverse bird species. Similarly, the gorilla enclosures at the San Diego Zoo utilize specialized mesh that supports the animals’ climbing behavior without compromising durability.

Lessons Learned

Common challenges in zoo mesh applications include managing the balance between visibility and strength and ensuring long-term durability against weather and animal impact. Solutions have been developed through material innovations and design alterations, such as using coated meshes for added longevity and designing enclosures that cater to the specific behaviors of different species.

Conclusion and Future Trends zoo mesh

Zoo mesh is crucial in modern zoos, providing secure, attractive enclosures that improve both visitor experience and animal welfare. Mesh design innovations are evolving, with new materials and techniques enhancing functionality and sustainability. Future developments might include smart meshes that monitor enclosure integrity in real time. Other advances could involve materials that blend more seamlessly into natural habitats. As zoos evolve, zoo mesh will play a larger role in creating safe, engaging, and educational spaces. This expansion is driven by technological progress and a commitment to animal conservation and visitor experience.

Return Policy

Return Policy Stainless Steel Cable Inter-Woven Mesh is the Perfect Choice

Stainless Steel Cable Inter-Woven Mesh is the Perfect Choice Stainless Steel Cable Opened Ferrule Mesh

Stainless Steel Cable Opened Ferrule Mesh Zoo Mesh: Enhancing Safety and Well-being in Zoological Parks

Zoo Mesh: Enhancing Safety and Well-being in Zoological Parks Zoo Mesh: The Key to Safe and Engaging Animal Enclosures

Zoo Mesh: The Key to Safe and Engaging Animal Enclosures